An aerospace company whose name has not been disclosed, would have supported Phase3D in this development.

Phase3D, an expert in-situ monitoring for additive manufacturing (AM), has just launched a toolkit that can help measure the quantity, in microns, of metal powder spread across the build area, certifying uniform distribution for every layer of every build.

Named “True Layer Thickness”, the Chicago-based company said its solution is a new in-situ monitoring solution for production scale AM.

The company said key features of this solution include:

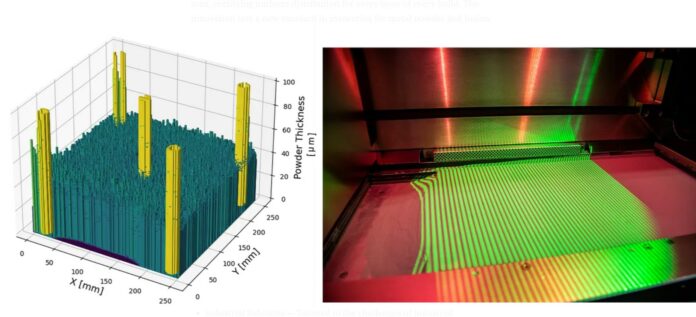

- Objective Data – True Layer Thickness uses patented Fringe in-situ monitoring technology to create quantifiable measurements, in microns, of how much powder is spread during the metal PBF process.

- Precision and Consistency – This toolkit ensures precise inspection of the amount of deposited metal powder for every layer of every build.

- Industrial Solutions – Tailored to the challenges of industrial manufacturing, True Layer Thickness addresses the requirements for industrial applications beyond aerospace including defense, energy, medical, and more.

- Seamless Integration – True Layer Thickness integrates seamlessly with Phase3D’s existing in-situ monitoring system, Fringe, which can be added to most metal AM machines to support product development to production.

While aerospace AM has been the foundation of this development, it should be noted that the solution would be ideal for all regulated industries seeking to advance AM to meet critical use applications – that is medical, energy and more.

Fringe in-situ monitoring and True Layer Thickness provide objective measurement data to inspect every build in real-time. This toolkit will be available for all Phase3D customers and can be seen at AMUG 2024, in Chicago, IL at Booth 101 in Salon D.

You can fin all other news related to AMUG here.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com