In partnership with Jacobs Space Exploration Group, the Marshall Space Flight Center, representing NASA, has shifted focus to advanced materials research, awarding a contract for the C1000 Flexmatic 3D Ceramic Printer to 3DCERAM Sinto, Inc.

This contract brings a new frontier for ceramic 3D printing as applied in space. The C1000 Flexmatic—one of the machines that can produce large parts and fully dense parts alike—will be crucial in fabricating small and large parts and supporting the development of materials that can sustain the difficult conditions of space.

This initial phase will be part of the Materials International Space Station Experiment (MISSE) program, a vital test project conducted to study the durability of materials in space. 3DCERAM Sinto will produce 20 sample parts dispatched to ISS next year.

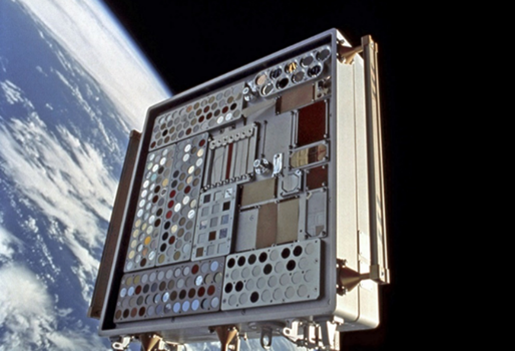

These will be mounted on a panel outside the ISS and go through extreme conditions in outer space for six months, enabling NASA to study the effects caused by zero gravity, solar radiation, and other space-related conditions on the ceramic materials.

In that respect, the MISSE program plays a huge role in NASA‘s ultimate goal of using materials in space vehicles and other extraterrestrial applications. The results of these tests will provide immense knowledge about how well 3D-printed ceramics perform in space and help produce flight-worthy hot structures and heat shields.

The fact that the C1000 Flexmatic can print small and large parts on its 320 mm × 320 mm platform allows NASA to discover extensive applications. This close collaboration underlines how Additive Manufacturing is increasingly key to space exploration as 3DCERAM Sinto becomes a part of NASA’s network of partners.

If 3D-printed ceramics can be integrated successfully into space missions, it will turn a new leaf in how materials will be created and used outside Earth. This partnership proves that 3D printing technology opens a new doorway for even tougher and more resilient materials to be deployed in space.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.