Nanoscribe, a BICO company, launches a new high-precision 3D printer intended for auto-aligned printing on fibers and chips. Named Quantum X align, the new 3D printer features capabilities that enable the printing of freeform micro-optical elements directly onto optical fibers and photonic chips. This brings the design and fabrication of micro-optical elements to new levels.

The Quantum X align provides robust and reliable alignment solutions for realizing efficient light couplers via Free Space Microoptical Coupling (FSMOC) between chips and optical fibers. The novel device opens up new horizons for imaging technologies using fiber and beam shaping applications, especially for hybrid packaging of photonic chips. The microfabrication system extends the capabilities of the groundbreaking Quantum X platform, allowing for a more straightforward process chain, relaxed assembly tolerances and no necessity of the costly and time-consuming active alignment and a further reduction of devices dimensions.

“With the addition of the new Quantum X align to our industry-proven Quantum X platform, we are enriching Two-Photon Polymerization with powerful alignment technologies that drive the ever-increasing demand in data communications, telecommunications and sensing applications,” said Martin Hermatschweiler, CEO and co-founder of Nanoscribe. “Our goal is to address the challenges of efficient coupling in photonic packaging and make high-precision 3D printing the technology of choice in integrated photonics,” added Hermatschweiler.

Advanced photonic packaging solutions for enabling tomorrow’s technologies

The new high-precision 3D printer unlocks unprecedented possibilities for photonic packaging, which is promising for developing more energy-efficient technologies with high data processing capacities. Photonic integrated circuits (PIC) will help to surpass the limited computing power of today’s microelectronics at a tremendously lower power consumption, driving applications in artificial intelligence or quantum computing. However, manufacturing of such devices requires new technologies for realizing microoptical interconnects. The new Quantum X align addresses these current challenges with innovative hardware and software solutions. Based on Two-Photon Polymerization (2PP) as the leading high-precision 3D printing technology, the Quantum X align achieves alignment accuracies in all spatial dimensions of down to 100 nanometers.

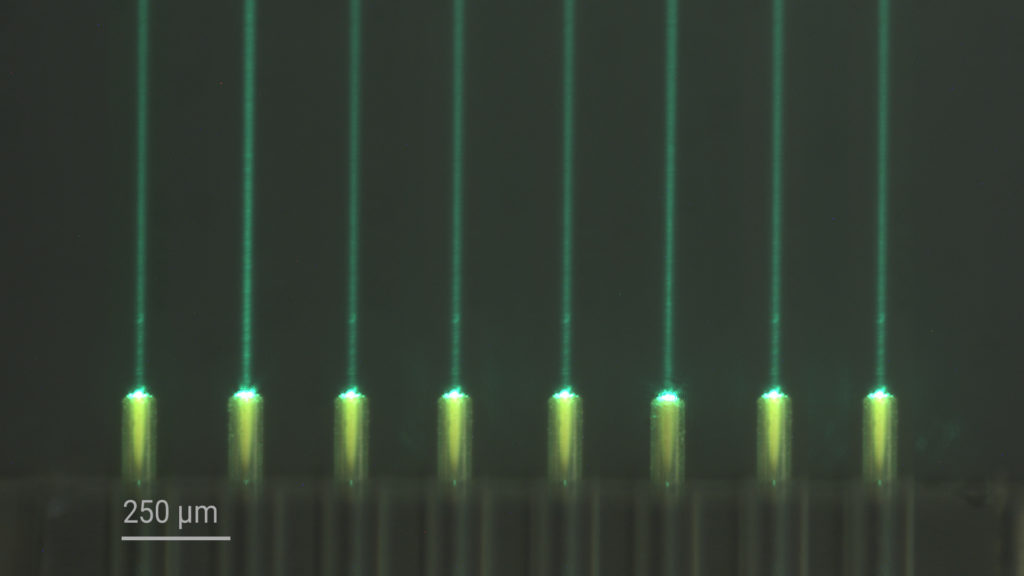

Nano-precision alignment for on-fiber and on-chip printing

Quantum X align allows for automatic 3D fiber core detection and automatic tilt compensation to precisely print on fibers or fiber arrays. The Quantum X align printer’s central feature for printing on photonic chips is a confocal imaging module for 3D mapping of substrate topographies combined with a fully automated alignment to predefined markers or waveguides.

Thus, Quantum X align makes it easy to 3D print freeform microoptics perfectly aligned onto the fiber core or attached to facets or waveguides on standard or customized optical chips. All in all, auto-aligned 3D printing significantly reduces complex chip-level mode field tuning, eliminates active alignment and enables novel and unprecedent use of freeform microoptics at optical interfaces.

This announcement follows the recent release of the Quantum X bio, a 3D bioprinter developed in collaboration with CELLINK.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com