The approach which involves the 3D printing of a metallic powder strengthened with ceramic nanowires, could be used to improve many other materials

As you may already know, Inconel 718 is one of the key 3D printing materials used for aerospace and energy generation applications. The team at MIT has recently explored a new approach to strengthen such type of superalloys so that it can withstand extreme conditions such as high temperatures and tensile stresses without failing.

As you may already know, Inconel 718 is one of the key 3D printing materials used for aerospace and energy generation applications. The team at MIT has recently explored a new approach to strengthen such type of superalloys so that it can withstand extreme conditions such as high temperatures and tensile stresses without failing.

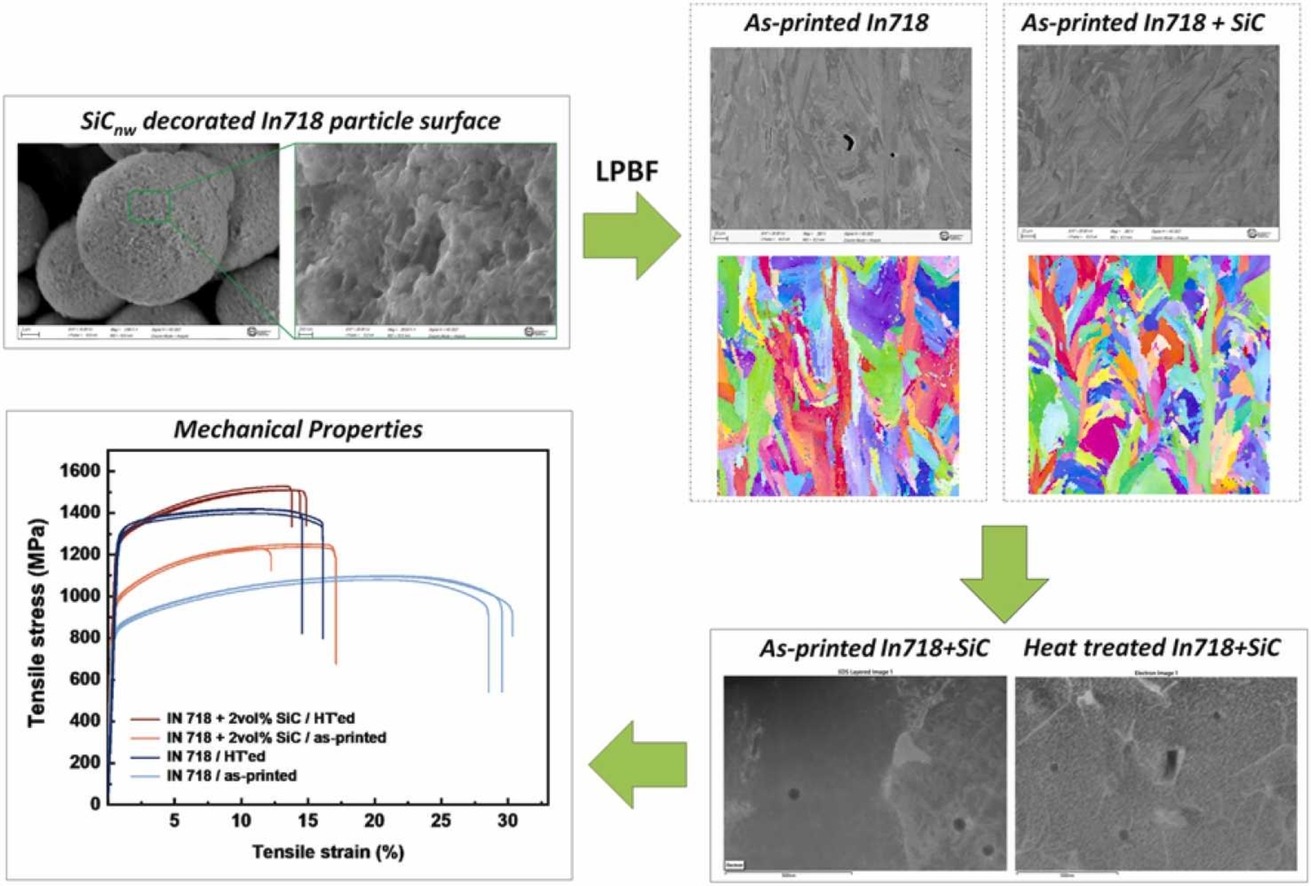

As a reminder, Inconel 718 can withstand extreme conditions such as temperatures of 700 degrees Celsius (about 1,300 degrees Fahrenheit). The research team at MIT mill commercial Inconel 718 powders with a small amount of ceramic nanowires, resulting in “a homogeneous decoration of nano-ceramics on the surfaces of Inconel particles.”

The resulting powder is then used to create parts via laser powder bed fusion, a form of 3D printing. That process involves printing thin layers of powder that are each exposed to a laser that moves across the powder, melting it in a specific pattern. Then another layer of powder is spread on top, and the process repeats with the laser moving to melt the pattern for the new layer and bond it with the layer below. The overall process can produce complicated 3D parts.

The researchers found that parts made this way with their new powder have significantly less porosity and fewer cracks than parts made of Inconel 718 alone. And that, in turn, leads to significantly stronger parts that also have a number of other advantages. For example, they are more ductile — or stretchable — and have much better resistance to radiation and high-temperature loading.

Plus, the process itself is not expensive because “it works with existing 3D printing machines. Just use our powder and you get much better performance,” says Ju Li, the Battelle Energy Alliance Professor in Nuclear Engineering and a professor in MIT’s Department of Materials Science and Engineering (DMSE).

Plus, the process itself is not expensive because “it works with existing 3D printing machines. Just use our powder and you get much better performance,” says Ju Li, the Battelle Energy Alliance Professor in Nuclear Engineering and a professor in MIT’s Department of Materials Science and Engineering (DMSE).

Xu Song, an assistant professor at the Chinese University of Hong Kong who was not involved in the work, comments: “In this paper, the authors propose a new method for printing metal matrix composites of Inconel 718 reinforced by [ceramic] nanowires. The in-situ dissolution of the ceramic that is induced by the laser melting process has enhanced the thermal resistance and strength of Inconel 718. Moreover, the in-situ reinforcements reduced the grain size and got rid of flaws. Future 3D printing of metal alloys, including modification for high-reflectivity copper and fracture suppression for superalloys, can clearly benefit from this technique.”

The entire research can be found here.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.