This new additive technology instantly creates complete parts using precision-controlled light.

Manifest Technologies (formerly Vitro3D), an advanced manufacturing startup out of the University of Colorado’s McLeod Lab for Optics & Materials Science, unveils at RAPID+TCT the Parallax Volumetric Additive Manufacturing (P-VAM) evaluation kit.

Parallax VAM pairs well with existing forming processes such as injection molding, opening new opportunities for production applications.

CEO and co-founder Camila Uzcategui emphasized the significance of the launch: “We founded Manifest to fundamentally reimagine additive manufacturing—moving beyond layer-by-layer printing to instant, multidimensional formation of solid parts using precisely controlled beams of light. At a time when the more mature additive technologies are beginning to stagnate, we view the debut of our P-VAM evaluation kit at RAPID as an invitation to forward-thinking partners to join us and manifest different.”

Key advantages of P-VAM

Key advantages of P-VAM

According to Manifest, the system can help achieve layerless 3D fabrication, as well as design freedom & adaptability.

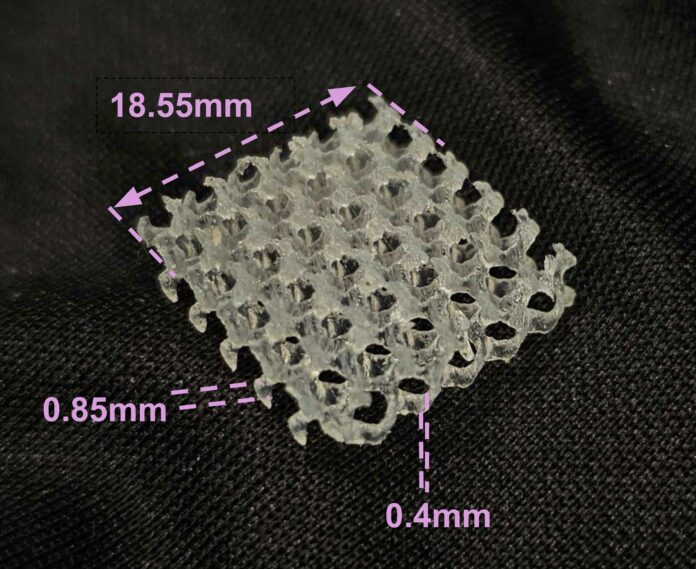

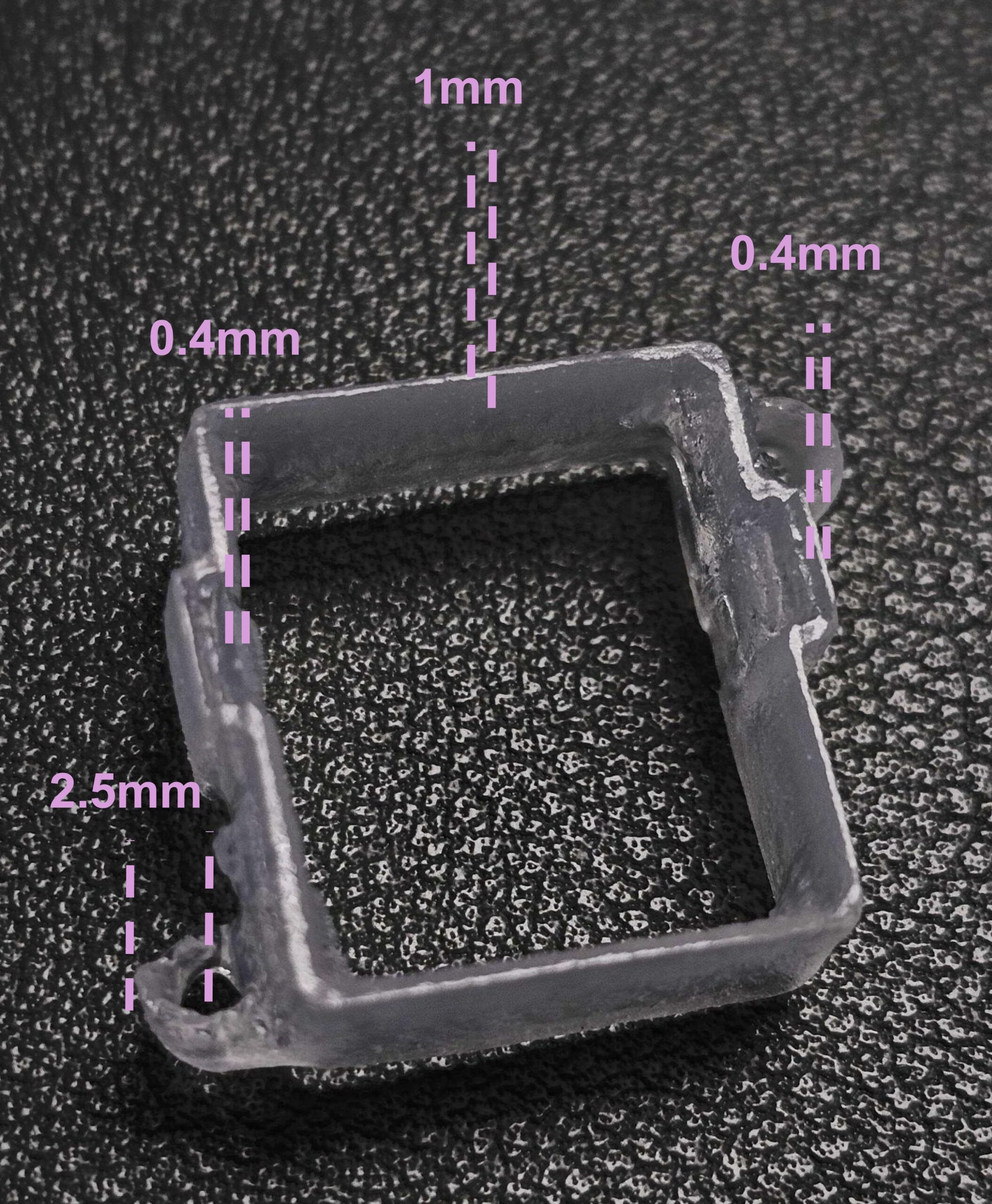

This means it cures liquid resin in three dimensions—eliminating layers and support structures—to produce intricate, fully solid parts 10–100x faster than conventional additive methods, unlocking entirely new mass-customization and scalable production opportunities.

Through its open platform approach, users can experience a diverse array of transparent photopolymer resins, including high-viscosity formulations, to precisely tailor materials to advanced applications.

Its production-line set up eliminates the need for traditional bulky print farms. P-VAM enables continuous, on-demand production directly within existing manufacturing lines.

With the launch, the company will allow engineers, R&D teams, and strategic partners to test and explore the potential of P-VAM.

Images’ credit: Manifest Technologies. Looking for a job in the AM industry or hiring new talent? You can post job opportunities on 3D ADEPT Media for free or explore openings via our job board. Stay connected by following us on Facebook, Twitter, LinkedIn & Instagram, and subscribe to our weekly newsletter for the latest updates. Have a story to share or want to be featured in our next digital magazine issue? Send it to editor@3dadept.com !