The first 3D racing yacht in the world is expected at the Mini Transat 2019 (the solo transatlantic race that covers about 4000 miles – 6437 km-) which starts in France and ends in Brazil. The largest component was recently shown at Rapid.

Daniele Cevola and Francesco Belvisi, founders of the Italian start-up Livrea want to discover how far emerging technologies could be useful in the building of racing yachts more competitive hence the collaboration with Autodesk which will bring revolution into the yachting world.

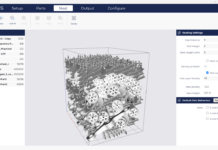

The challenge being to reduce production time and cost related to Sicilian yachts traditionally built, they made great use of Autodesk Fusion 360 software to design the hull of the yacht that was printed with advanced, multi-material, polymer composites. The latter guarantee a higher accuracy and lightness than wood.

The challenge being to reduce production time and cost related to Sicilian yachts traditionally built, they made great use of Autodesk Fusion 360 software to design the hull of the yacht that was printed with advanced, multi-material, polymer composites. The latter guarantee a higher accuracy and lightness than wood.

To print components of such a large size, Autodesk called upon SABIC, international leader in thermoplastic technology.

Experts used two types of carbon fiber for the hull’s outer layer and the inner lattice support structure.

Experts used two types of carbon fiber for the hull’s outer layer and the inner lattice support structure.

For Massimiliano Moruzzi, senior principal research scientist at Autodesk, ‘’Livrea is a great example of a company that is committed to exploring the future of making things and shaking up its industry. Together with SABIC, we are using the very latest in advanced manufacturing techniques and materials to demonstrate what is possible in the here and now. Autodesk is honored to help Livrea on its quest to manufacture the world’s first 3D printed yacht and we look forward to seeing how these new processes influence other industries moving forward.”