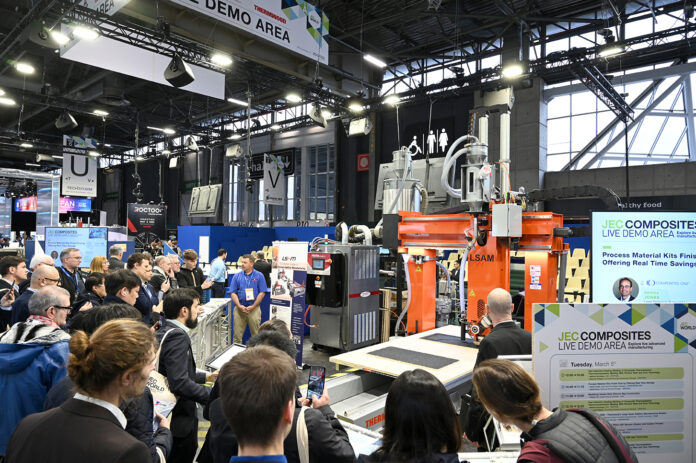

JEC 2026, the largest composites event in the world, is the opportunity for composites AM machine manufacturers to stand out in a market still dominated by traditional composites manufacturing.

One of the companies that is coming back to the show is Thermwood. After a successful 2025 edition, the company will raise awareness on LSAM’s capabilities with a live demo of drone molds.

This LIVE Demo Area will take place in Hall 6 at JEC World 2026 in Paris, France on March 10th-12th.

The molds will be printed on the LSAM AP510 Additive Printer using advanced carbon fiber reinforced materials, with a different material supplier featured each day (Airtech, Sabic and Techmer PM).

The company says it will also have completed drone bodies on display, produced from the molds by its partner, the Aria Group.

Thermwood will also showcase the breadth of material options and design flexibility available on LSAM systems, along with patented features that underpin their industrial positioning. It plans to discuss collaborative projects, ongoing research initiatives, and case studies that illustrate how these developments contribute to a stronger knowledge base and continued innovation in large-scale additive manufacturing.

Eduardo Barocio, Director of Composites Additive Manufacturing and Simulation (CAMS) Consortium at Purdue University’s Composite Manufacturing & Simulation Center will also be on hand to demonstrate their Additive3D software.

Technology capabilities on display

Additive3D is a powerful tool that simulates workflow and predicts the printing and as-manufactured performance of parts produced through extrusion deposition additive manufacturing.

The LSAM Additive Printer systems feature a single-gantry, moving-table configuration and are available in two table sizes: 5 ft × 5 ft (1.5 m × 1.5 m) and 5 ft × 10 ft (1.5 m × 3 m).

The 5 ft × 10 ft table can be configured either as 5 ft (1.5 m) wide with 10 ft (3 m) of front-to-back motion, or 10 ft (3 m) wide with 5 ft (1.5 m) of front-to-back motion. The choice depends on several factors, including how the system fits into existing factory floor space.

The specially designed, highly rigid tab-and-slot structural steel gantry also incorporates a fume-extraction system that pulls print fumes through activated charcoal filters, removing them and improving air quality around the machine.

The company will also have its regular booth staffed by its knowledgeable sales team who can help answer any questions you might have (Hall 6 P52).

*We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.