Theoretical physicist by training, Cedric Michel specialized in applied mathematics. A mission carried out, as part of his training, at the London-based Nasa office brought him to 3D printing. A mission that resulted a few years later in a breakthrough in his professional career, since he discovered a passion, questioned a number of topics (and still does), but above all, is driven by the desire to be part of this 4th industrial revolution.

Speaking of the breakthrough mentioned above, Cedric and Victor Roux, his partner, created Pollen AM in 2013, a company that is committed to addressing issues raised by materials, especially pellets.

After a few years of research and development, the company unveiled in 2016 its first range of 3D printers on the market, the PAM Series P, which is compatible with all thermoplastics, including elastomers, and most recently the PAM Series M, which processes metallic materials in the form of Metal Injection Molding (MIM).

Why this interest in TPE? What are the advantages of 3D Printing with pellets materials? What about the sectors of application? Cédric Michel answers these questions in this #OpinionoftheWeek.

Pollen AM, an adventure that began 6 years ago

It all began when Victor, Cédric and a few members of their team decided to address the issue of materials and possible solutions that could be brought out using pellets as a raw material.

Two years later, after a successful fundraising round which was carried out in 2014, the company was able to achieve its first recruitments and at the end of 2016, unveiled and started the commercialization of its first system.

“It took time and maturity to realize that materials are a key component to ensure quality and profitability in this revolution,” says Cedric. A wake-up call that gives rise to a leitmotiv, “Your Chemistry Inside”, and allows Cedric, Victor and their entire team to provide customized solutions to customers and prospects every day.

What advantages pellets offer to 3D printing?

“From an economic point of view, pellets are interesting because they are the most widespread materials, available at the lowest price with the best chemistry. Furthermore, production costs are lowered because they are the industry standards when it comes to mass manufacturing.

Moreover, it should be noted that such type of materials does not affect the supply chain.

The most important point is that the existing chemistry is the ideal one. It has been validated by various industrial markets. We will neither get close, nor mimic the required properties.”

Materials and the PAM technology

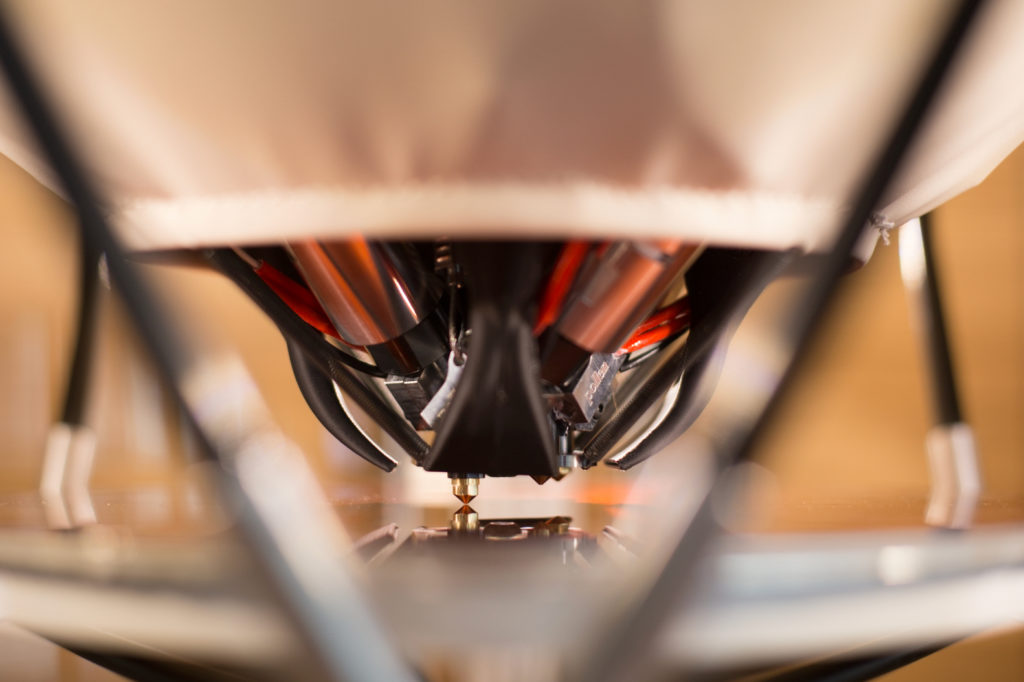

Pollen AM has implemented a patented technology called PAM (Pellet Additive Manufacturing). By using industrial grade pellets for 3D printing, Pam technology enables to run small & medium scale productions while making profit. Furthermore, it enables to acquire the desired properties.

The PAM technology is integrated in the PAM Series P systems, which process polymers and elastomers, and the PAM Series M systems, which allow the manufacture of metal parts in MIM (Metal Injection Molding) feedstock.

Speaking of these materials, Cedric explains: “If an elastomer, polymer, or polymer composite material works to a certain extent with injection molding, then it will work with our technology. We have 100% validation on all customer and prospect requests at this level. »

As for the duration of validity of such type of materials, Cedric adds that “elastomers are an extremely protean family. It takes a maximum of 3 weeks to obtain satisfactory results and much less if the materials to be treated are from an already validated family.”

The main challenge encountered using pellets in an AM process

The list of materials that must be compatible with the PAM technology is not exhaustive… The challenge is therefore to successfully automate their validation, so that manufacturers can move as quickly as possible from the design phase to the production phase.

Sectors that already benefit from PAM technology

“Apart from the usual sectors such as aerospace, manufacturing and medicine, we stand out from the crowd by supplying the home appliances sector.

For the latter sector, the production of spare parts is crucial. Speed and reduction costs are the key words.

To turn our customers’ applications into success, we give them access to all the settings of our system. This is a predominant theme in industrial issues: setting up manufacturing parameters.”

Outlooks for 2019

“2019 would certainly be “the year of the industry”. Pollen AM should make a big move with regards to its size, therefore should be able to accelerate the delivery process of its systems and move forward on the development of the next generation of systems.”

For further information, follow us on our social media and subscribe to our newsletter! All images: courtesy of Pollen AM

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});