I have always compared a 3D printing file format to a language that a 3D printer can understand. Just like there are languages different populations can speak, there are 3D printing file formats some 3D printers can process even if they are powered by different technologies, and there are file formats that are proprietary to some 3D printers. How does one make the difference between the file formats and what are the pros and cons that one should know? The article below provides insights into key 3D printing file formats and how they are used.

It may seem trivial to discuss such a topic at this level of maturity of AM. Yet, we shouldn’t forget that going back to basics is not only for beginners in AM, it’s also for advanced users to realize the advancements made in the first stages of the 3D printing process.

To beginners of AM, the preparation phase before 3D printing requires undertaking the 3D modeling and slicing steps. 3D modeling consists in using software to create a mathematical representation of a 3D model. Slicing consists in converting a 3D model into a series of horizontal layers and generating the necessary instructions for a 3D printer.

That being said, no matter what the 3D printing file format is, the function remains the same: turning raw materials into solid parts.

So far, we have identified about 10 different types of 3D printing file formats: STL, OBJ, AMF, 3MF, Gcode, X3G, VRML/X3D, FBX, PLY, STEP and IGES. Of all these formats, the most widely known ones include STL, OBJ, AMF, and 3MF.

A few words on the main 3D printing file formats

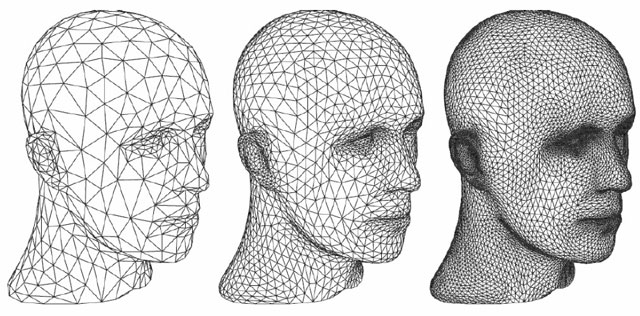

STL (which stands for Standard Tessellation Language) is probably the first format any 3D printing user will hear about. It breaks down a 3D object into triangles or facets, creating a mesh of the part to 3D print. The mesh represents the surface of the part; it allows that file to be printed layer-by-layer until the solid object. STL files simply contain the surface geometry of a virtual 3D object, with no other properties. This file format is universally supported by 3D CAD software.

OBJ derives from Wavefront Technologies’s Advanced Visualizer software. While most software will export to OBJ, its use is acknowledged in color 3D printers. Normally all slicers accept OBJ files as input. The 3D data entails high-quality geometry, texture information, and full color.

AMF (stands for Additive Manufacturing File). This recently created format can provide more information and higher accuracy than just the mesh surface representation. Developed with an eye towards addressing some of STL’s limitations, AMF brings color, materials, and even multiple textures into the mix – not to mention that it handles well geometry.

If AMF is often seen as STL’s successor, 3MF ( which stands for “3D Manufacture Language” ) can be seen as the kid of superhero parents. As a matter of fact, it benefited (and still benefits) from a lot of media hype due to tech giants (Microsoft, Autodesk, HP, Viaccess-Orca, etc.) who decided to join forces to create and enhance it. It can integrate the model’s geometry, as well as details such as color, texture, and even printing directions, all in a single file.

Pros and cons to take into account

| 3D printing file formats | Pros | Cons |

| .STL | Easy to create | Does not include information about color, texture, or material properties

May not deliver the accuracy required for curved or organic shapes. |

| .OBJ | Better for curved/organic shapes | Can be difficult to work with when creating very detailed parts

Similar to .STL in that it contains 3D geometry information only (vertex normals, geometric vertices, polygonal faces and texture coordinates.) |

| AMF | Provides a lot of information

Better for complex applications |

May not be compatible with all 3D printers yet

Slow adoption (lack of marketing strategy to position itself as the necessary successor of .STL |

| 3MF | Provides a lot of information, well known and open source

Able to use a compressed ZIP format |

Raises concerns about how much of an open-source format it is going to be in the future |

Other 3D printing file formats

While this article focuses on the most widely known file formats, one should keep in mind that one can print from basically any 3D file – even though they are not initially designed for 3D printing.

G-code, short for “geometric code,” serves as the final output of the slicing software which converts CAD and VR objects into movement instructions that a 3D printer can interpret.

FBX: this proprietary file format owned by Autodesk is ideal for interoperability between Autodesk software programs. Just like VRML and its successor X3D, its intended use is for rendering effects.

PLY (Polygon File Format): Designed to store geometrical data generated by 3D scans. Besides its geometrical elements, it can encapsulate elements such as color, texture maps and transparency. For 3D printing, one can convert a PLY file into the format accepted by the 3D printer.

STEP and IGES remain the CAD standards for engineering applications. Rather than polygons, these file formats use complex NURBS representations for precision. Their use in 3D printing is often subject to debate as 3D printers often require simpler data.

Key considerations to select a 3D printing file format

3D printing file formats can be divided into two categories: 3D modeling files that contain all design information and sliced files that contain instructions for the 3D printer based on the 3D model files.

It may seem redundant in the AM world but the choice of a file format depends on several things including the purpose the user is looking to achieve. Answering a couple of questions might help.

What are the project requirements? Does the part require high details, textures and color – then you might want to go for OBJ or 3MF formats for instance.

What/how is the 3D printer compatibility? Some 3D printers have proprietary file formats (like MakerBot and its .X3G file format); others just work best with some formats so just ask the OEM before purchasing the machine.

Is the file format influenced by some software tools? Ensuring your file format, printer, and software work seamlessly together is critical. Think of it as a finely tuned orchestra; if one instrument is off-key, the whole symphony is affected. It all comes down to what enhances the project the best.

This dossier has first been shared in the May/June edition of 3D ADEPT Mag.