Renishaw recently implemented a new process monitoring software. Called InfiniAM Spectral, the software would facilitate users’ understanding on the company additive manufacturing systems.

The reality is that manufacturers still face some hurdles to AM in critical applications, process stability and part quality. The complexity of laser powder-bed fusion (LPBF) might be taken as example. Since it produces parts from millions of laser exposures, the process is supposed to be highly accurate. The only thing is that sources of variation should be taken into account because they lead to anomalies that influence the longevity of the part.

And there comes the monitoring software…

Regarding this situation formerly described, InfiniAM Spectral gathers melt-pool data to enable traceable production and process optimisation. “The software enables data capture, presentation and analysis, representing a powerful tool for developing a deep understanding of the AM process.”

The software integrates two measurement functions in the sensor modules: laserVIEW and meltVIEW.

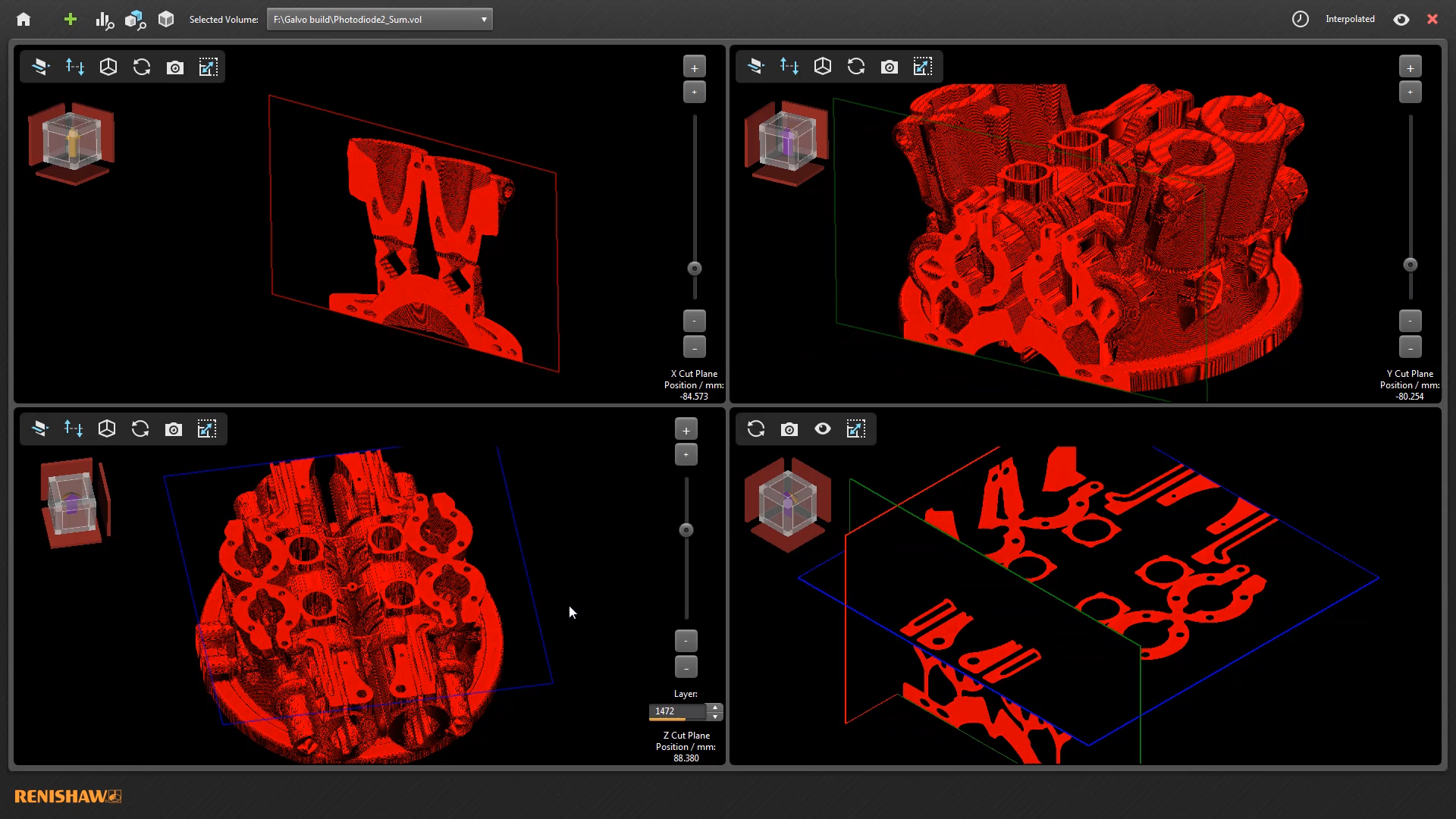

Thanks to a photosensitive diode, the first module can measure the intensity of the laser energy. As for MeltVIEW, it captures emissions from the melt pool in the near-infrared and infrared spectral ranges. According to the company, “these two sensor signals can be compared to help identify discrepancies.”

“MeltVIEW and LaserVIEW stream data across a conventional computer network on a layer-by-layer basis, so manufacturers can analyse process monitoring data in real-time. As the build progresses, the data is rendered live in 3D for viewing in InfiniAM Spectral. The engineer can compare the data from each sensor to identify any deviations, which may indicate the presence of anomalies that could lead to defects.”

InfiniAM Spectral would be a big advantage in the production of series of identical parts in high-value applications.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter! Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com