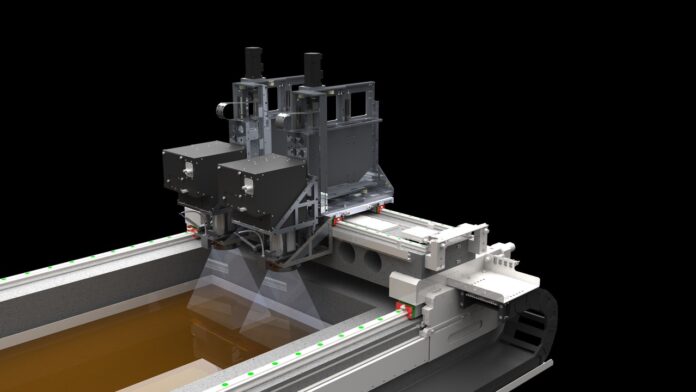

IN-VISION Technologies AG, a manufacturer of high-precision optical systems, has just launched a gantry system that could help manufacture parts with bigger sizes in DLP 3D printing.

It consists of an extremely precise portal and up to four high-power HELIOS X Light Engines scrolled over the image plane. This combination opens up previously unknown possibilities: The basic system is equipped with two projectors and a width of 415, can be expanded to nearly one meter and handles almost unlimited building-area lengths. The precise alignment of the multiheads moving over the building area is managed live with sensor-based compensation.

IN-VISION chose Helios X as projection system. As a reminder, the HELIOS light engine is a UV light projector for additive manufacturing that was specifically developed to achieve the highest illumination intensity to allow for faster prints and the use of highly reactive photopolymers.

Recently re-designed electronics enable dynamic curing while the projectors traverse the building area. This offers several cutting-edge possibilities for system designers:

- Up to 16 Watt pure light power per projector in the image plane

- A wide variety of optical lenses, from 6um pixel size

- Completely rebuilt electronics with an open FPGA on-board, enhancing device intelligence and increasing customization options

- Designers have the choice between Gigabit Ethernet and PCIe interfaces.

“No, we are not about to start building printers on our own; this is a job we are happy to leave to our customers”, explains Christof Hieger, CTO of the Austrian Optics Specialist IN-VISION, “but we love to share our know-how with them and provide them with turnkey solutions for their projects.”

Applications for the new gantry system include 3D printing, Lithography, and Screen Printing with similar requirements.

“We give every developer a compelling infrastructure offering almost unlimited possibilities”, explains Christof Hieger, In-Vision´s CTO. “The onboard system is the next step in merging our superior optical accuracy with powerful software options.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com