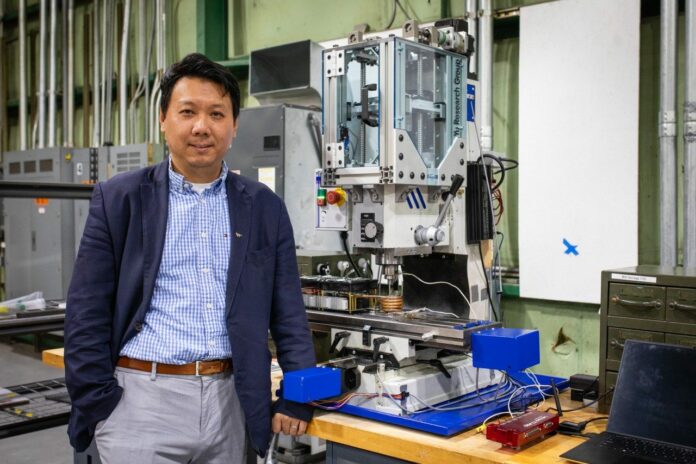

Creating a shape-memory ceramic that can be manufactured at scale without breaking, that’s the challenge that Hang Yu, associate professor of materials science and engineering at Virginia Tech, has been trying to address.

For those who do not know, shape-memory ceramics change their internal structure in response to stress or heat, then return to their original shape. They’re useful because they can move or absorb energy without gears or moving parts, a trick seen in metals like nickel-titanium alloys. But getting ceramics to play along has been a tougher nut to crack.

Using additive friction stir deposition to embed functional ceramic particles into metal, Yu and his team were able to achieve strong, defect-free material that can phase-shift under stress to dissipate energy.

Unlike normally brittle ceramics, the new material can be 3D-printed in bulk with full density in the as-printed state, opening up possibilities for practical applications in defense, infrastructure, aerospace, and even high-performance sporting equipment.

“This composite can afford tension, bending, compression, and absorb energy through stress-induced martensitic transformation,” said Yu. “In that sense, it’s multifunctional. That allows us to move toward making big things with the potential for real applications.”

It’s “like putting chocolate chips into cookie dough,” Yu said.

The new approach embeds tiny shape-memory ceramic particles into metal, “like putting chocolate chips into cookie dough,” Yu said. The mixture is then fed into an additive friction stir deposition machine, an advanced manufacturing tool that spins raw materials fast enough that they meld together without melting. The resulting composite metal contains evenly distributed ceramics that can shift without breaking the whole structure.

With this first demonstration of stress-induced phase transformation at a visible, bulk scale, the new material may bridge the gap between academic innovation and real world applications in industry, such as vibration damping or impact absorption in defense systems, aerospace, infrastructure, even sporting goods.

“For the first time, this research creates bulk shape-memory ceramic–metal matrix composites using a scalable, solid-state 3D-printing process,” Yu said.

*We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.