It often happens that the first time I read or hear the name of a company, without really “googling” it, I try to imagine what it does and what products or services it provides. When I first saw the name “Mosaic Manufacturing“, it immediately made me think of an “ecosystem“, and it turned out after my conversation with Mitch Debora, that I was right. The company enables manufacturers to create an ecosystem in the additive manufacturing industry.

Today, my first impression makes sense – given what you’ll read in the lines below -. However, if Debora and I had had this conversation three years ago, when the company was coming out from its stealth mode with the launch of Palette, I think I would have concluded that something was wrong, because the symbolism of the word “Mosaic” makes you expect to discover more than one product.

I don’t know if everything has been planned this way from the very beginning or if it was a series of coincidences in their adventure, but it seems to work well, and that’s all that matters.

So, about 7 years ago, before embarking on the “Mosaic” journey, Debora was working in a 3D printing service and realised that there was a strong demand for “multi-material 3D printing” but very few tangible and affordable solutions were available on the market.

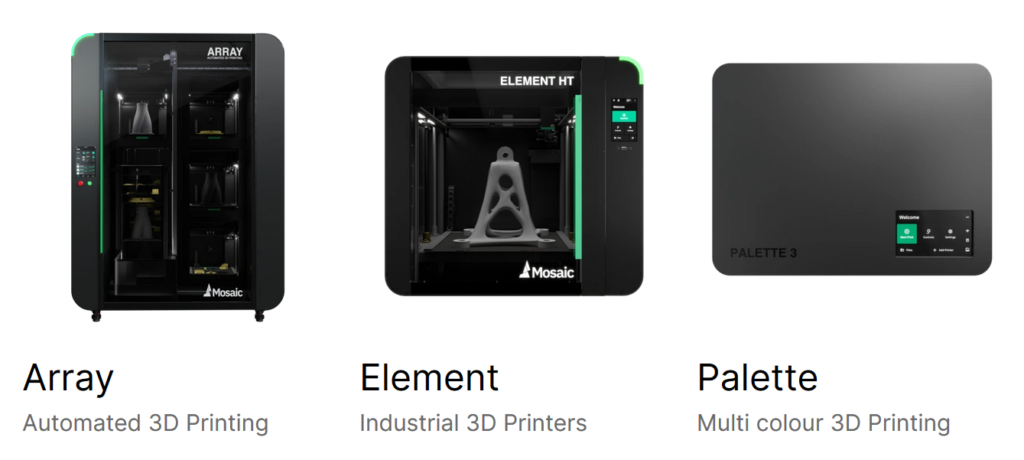

Together with his co-founders, they created Mosaic Manufacturing to help industries achieve multi-material 3D printing as part of their production. That was in 2014. They came out from their stealth mode in 2018, with Palette, their flagship product, a rather unusual 3D printing accessory that makes it easy to turn a normal single extruder device into a multi-colour 3D printer. It’s convenient, it’s affordable, and it doesn’t require you to invest in a new 3D printer to print with multiple materials.

For those who have never used Palette, note that the multi-material aspect of the solution enables a soluble support material to print complex geometries with internal support requirements. Furthermore, this multi-colour functionality is ideal for part serialisation, and simulation of overmoulded parts; not to mention that the material handling automation feature helps to unlock spool-to-spool printing; facilitating therefore the switching of spools between prints, or during prints.

Since the launch of the first “Palette”, the company has gradually improved the design and capabilities of the solution and now offers different versions of the product.

Over time, the team realises that instead of enabling multi-material 3D printing with a single FDM 3D printer, they may need to look for a way to help industries increase production.

“Scaling up 3D printing production with regular 3D printers is not really effective. A single operator may need to make thousands of parts a day hence the need for efficient production equipment for 3D printing parts,” Debora explains.

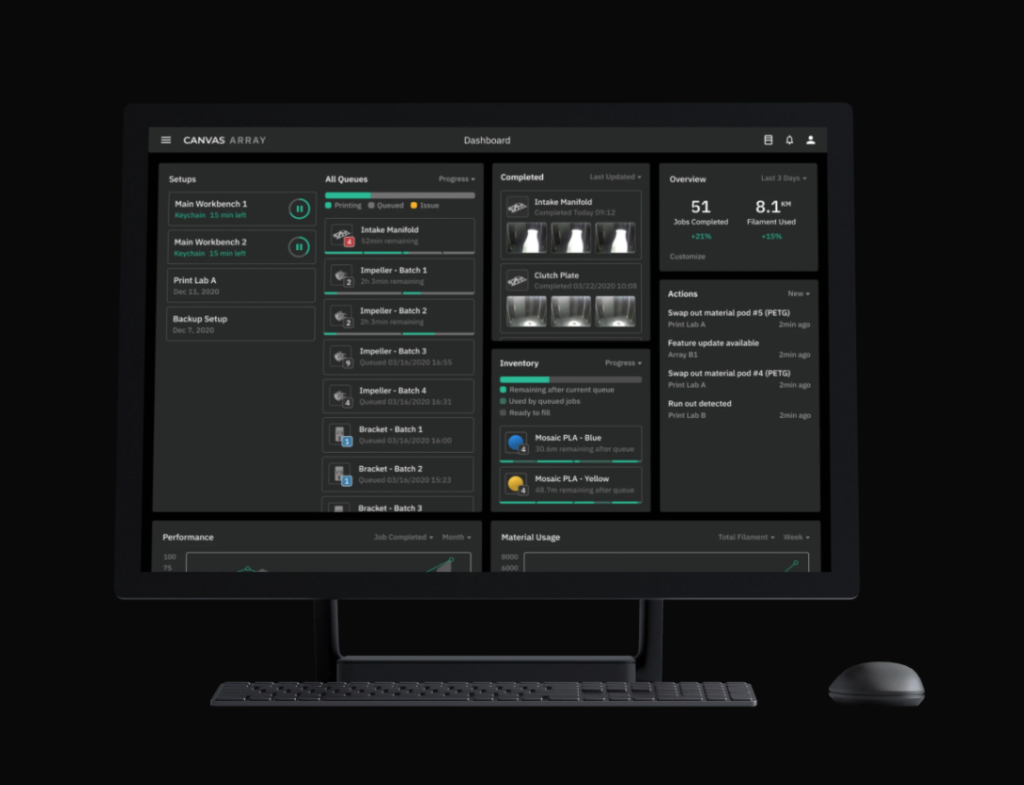

Therefore, the team began to imagine the development of 3D printers capable of supporting large-scale production. However, before the launch of Element and Array – equipment developed for that purpose – Mosaic has added new materials and Canvas to its portfolio of products.

Our guest in this Opinion of the Week believes in investing in the capabilities of a software platform, for today and tomorrow. For Debora, “this is a pivotal tool to handle everything that happens during production. It has become a factory management tool. Engineers are looking for more than slicers, they need to monitor and predict manufacturing.”

And the ecosystem is growing with Element and Array

To understand how Element or Array could be useful, it’s crucial to understand the problem that led to these developments and that problem is costs.

“The problem is usually the price at scale. When you realize that the price of the final product is often the same as prototyping, then 3D printing is no longer viable”, the CEO notes.

Since the costs do not always decrease while one prints, as it is the case with other manufacturing processes, and since the manufacturing hours are likely to increase while one manufactures, Mosaic has decided to automate the printing process with a new production line: Array.

At the heart of the Array production line is the company’s Element HT 3D printer. With a build volume of 355 x 355 x355 mm (14 x 14 x 14 inches), a build plate that can reach 120 degrees Celsius, the Element HT integrates a Palette material handling system that allows for printing with eight different materials or colours from a single nozzle, which can withstand up to 500 degrees Celsius.

Debora explains that the Array line is built from four Element HT 3D printers and a robotic system that replaces the build plates after each print. “Array can print for several hours without any human intervention and up to 32 materials at the same time,” he adds.

For manufacturers who are looking to mass-produce, Mosaic has developed, “Array Production“, a production line based on the same concept as the previous one but which integrates 24 3D printers and which can print during 72 hours without any human intervention.

Moreover, if you ever ask yourself how post-processing looks like with these machines, then Debora recalls that, “many times, no post-processing step is required when it comes to FFF 3D printing. As a matter of fact, that’s one of the major advantages of this process compared to other AM technologies. But, if for any reasons, the operator would require some post-processing steps, then Mosaic offers two types of support for this stage.”

Beyond mass production … applications

While it is easy to imagine that Mosaic’s equipment can serve the vertical industries that we are familiar with (automotive, aerospace, etc.), it is worth noting those industries we least expect; industries like textile for example.

One of Debora’s favourite applications has been achieved with Athletic Knit (AK), a manufacturer of sports team uniforms and apparel.

Both companies have been working together during the past years to improve production throughput and remove pain points in the traditional sewing process, all while maintaining the high-quality jersey product line that AK is known for.

In order to keep up with demand following AK’s integration of automated customization and quoting web-tool, Mosaic’s Array FFF 3D printing system served as an in-house solution for the mass-production of jersey decorations. Mosaic helped reduce production costs, while increasing throughput and streamlining the production ordering flow process with Canvas.

The manufacturer explains in its report that although fabric materials make up the base layer of most jerseys, the component with the most variation and customer input are the decorations made from layers of a material called twill. This includes logos, name bars and lettering/numbering on the front, sleeves and rear of the jersey. For logos in particular, these are often unique parts custom made from multiple colours, and multiple finishes of the same material. Each jersey could have up to 7 custom decorations, in any number of colours and materials, thus making the complete process very involved.

In the end, not only did Mosaic enable to increase the number of decorations made in a single day, the company’s equipment met AK’s requirements for “greater customization without adding risk, workflow complexity or cost”.

As mentioned at the outset, it all started 7 years ago with Derek Vogt, Chris Labelle and Mitch Debora at the heart of this journey. In the meantime, about 30 people joined them, 30 people who share the same mission for making multi-material 3D printing a reality and something tells me that it won’t stop any time soon.

All Images: Mosaic Manufacturing – Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com