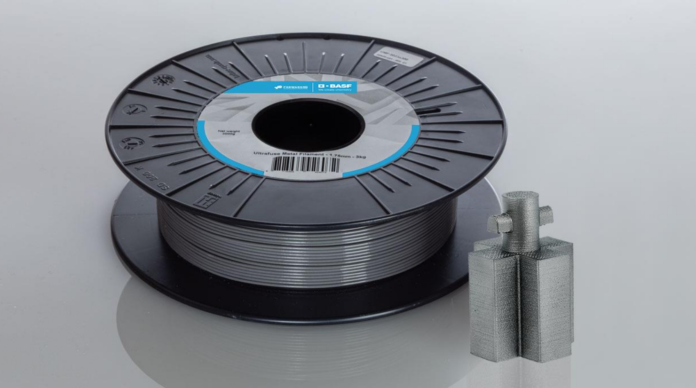

It is as if it was yesterday that BASF launched its first metal filament for FFF 3D Printing, the Ultrafuse® 316 L. Yet today, Forward AM, the AM brand of the global group reveals Ultrafuse® 17-4 PH, a material that enables safe and cost-efficient printing of metal parts in 17-4 stainless steel on common FFF printers.

Making metal parts on the most accessible 3D printing process

The process of producing metal parts with this new material is quite similar with the former one. After the subsequent industry-standard debinding and sintering process, the final 3D printed part is 17-4 stainless steel.

With its high mechanical strength and hardness, the new 3D printing filament is ideally suited for a wide range of applications such as tooling, jigs and fixtures, and functional prototypes. Good corrosion resistance and the ability to be fully heat treated to high levels of strength and hardness make Ultrafuse® 17-4 PH a good candidate for a range of industries including petrochemicals, aerospace, automotive, and medical.

Ultrafuse® metal filaments are specifically developed to work on all common opensource Fused Filament Fabrication (FFF) printers from beginner to industrial level, making it one of the easiest and most cost-effective technologies in metal Additive Manufacturing. FFF enables the production of hollow structures and lightweight designs. Additionally, users benefit from the traditional advantages of a nonoxidizing metal, such as corrosion resistance and outstanding strength.

“Ultrafuse® 17-4 PH is an outstanding result of our strong R&D commitment. We filamented more than 10 different metals from titanium to tool-grade steels, and several alternative materials to print support structures within this year. Going forward we will continue to introduce the new filaments that the market and our customers demand,” says Firat Hizal, Head of Metal Systems Group, BASF 3D Printing Solutions. “We have already established a distribution network that collaborates closely with our debinding and sintering service partners in different regions, and can thus deliver an integrated end-to-end solution. We are proud to extend our portfolio with Ultrafuse® 17-4 PH,” explains Firat Hizal.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com