Amorphous Metals, also called metallic glass alloys, differ from traditional metals in that they have a non-crystalline structure and possess unique physical and magnetic properties that satisfy several needs in terms of mechanical resistance, non-magnetism, environment resistance, biocompatibility. Such type of solutions opens new design possibilities for a wide range of industries, especially for industries that require automation solutions. Heraeus demonstrates it through one application.

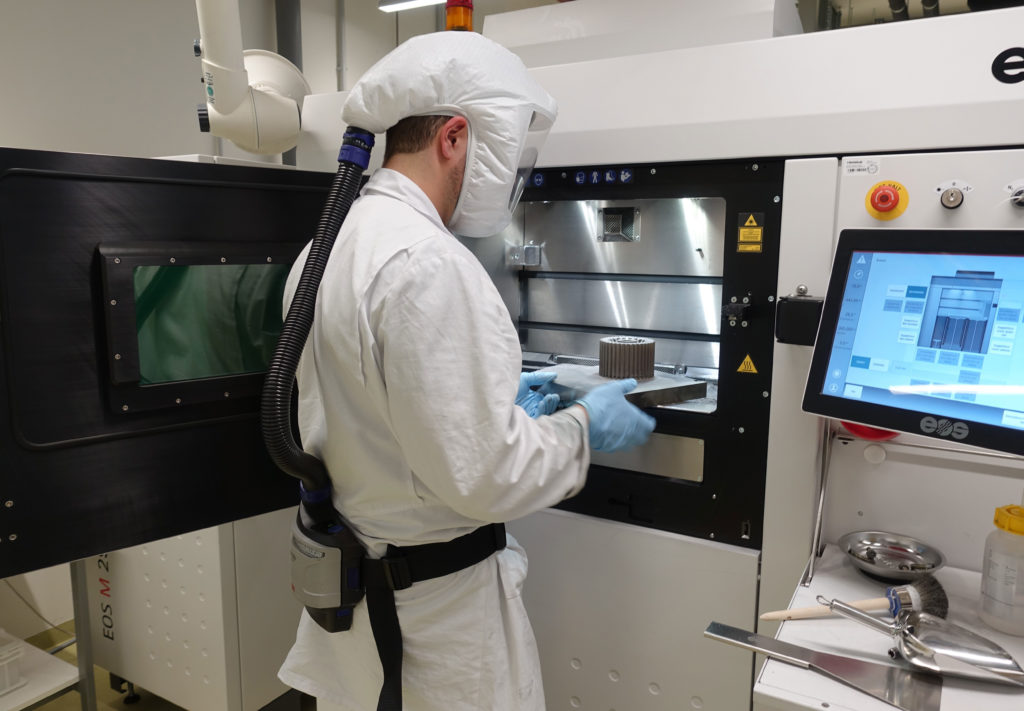

The Germany-based company provides a wide range of solutions across industries. In the AM industry, the company is recognized for its materials solutions. As part of its additive manufacturing activities, Heraeus has produced a world record additive manufactured gear wheel made of amorphous metals.

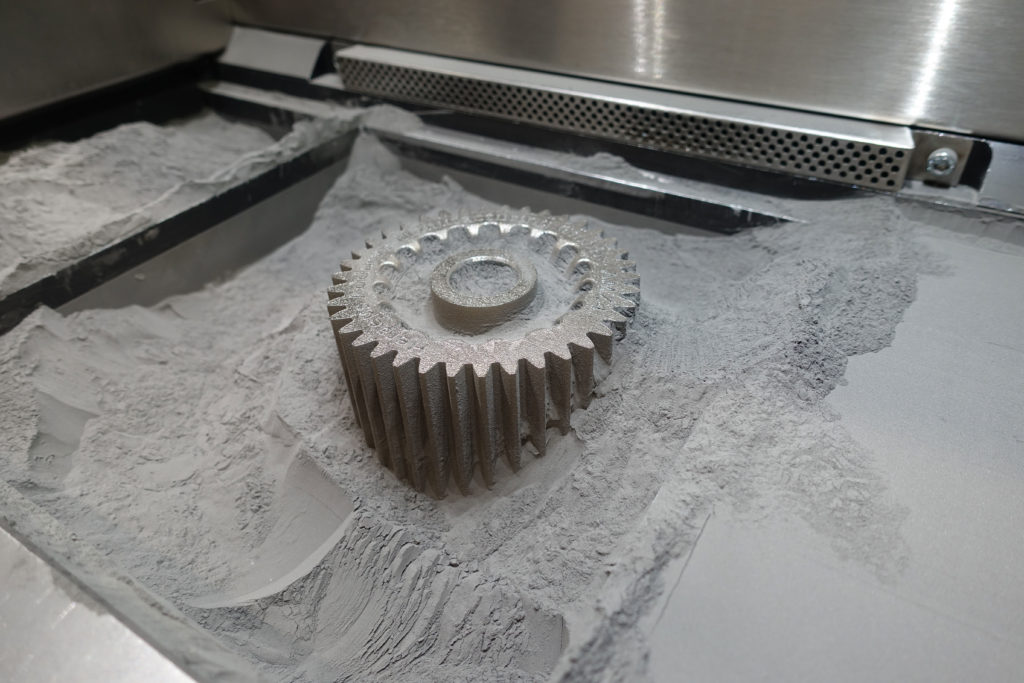

The gear wheel

Gear wheels are usually quite heavy due to the materials and the manufacturing process they require. In this case, Heraeus succeeded in producing a 2KG part thanks to high cooling rates of mainly over 1000 Kelvin/second. This technique also enabled to easily process amorphous metals.

Because the topology of the gear was also optimized during development, material and process experts were able to reduce the weight by 50 percent compared to conventional manufactured versions. Heraeus achieves this performance using a commercially available laser melt printer, a system that enables the company to save materials.

“Using 3D printing also reduces overall production costs. With conventional methods, making complex parts require numerous process and manufacturing steps. Several individual pieces have to be produced and then assembled into a unit. However, 3D printers accomplish this in a single process. Following assembly in the printer, moving parts are immediately ready for use and fully functional”, explains the company.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com