HeatFlow recently completed its Series E financing, securing $240 million. The financing will enable the company to develop its commercial expansion of the HeartFlow® FFRct Analysis, continued technology innovation and additional clinical studies. Investors such as Wellington Management and Baillie Gifford & Company took part in the financing.

“This financing will enable us to drive commercial success of the HeartFlow Analysis, which is poised to become the global standard of care in the diagnosis of coronary artery disease,” said John H. Stevens, M.D., president and chief executive officer of HeartFlow. “Given our recent momentum with clinicians, the Centers for Medicare & Medicaid Services, commercial payers and strategic collaborators, we are well positioned for growth.”

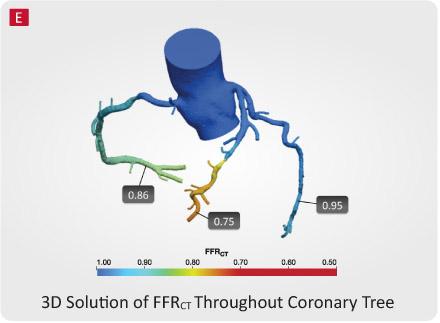

The HeartFlow Analysis

The HeartFlow is a non-invasive technology that creates a personalized 3D model of the heart to help clinicians diagnose and treat patients with suspected heart disease.

Experts have made progress in developing and commercializing the non-invasive technology. Today, clinicians used this technology at more than 80 medical institutions around the globe. In the United States for instance, several commercial payers issued positive coverage decisions and the Centers for Medicare & Medicaid Services (CMS) assigned a New Technology APC payment for the HeartFlow Analysis. Furthermore, the National Institute for Health and Care Excellence (NICE) in the U.K. issued a positive guidance recommendation for the use of the HeartFlow Analysis.

Speaking about heart disease and the involvement of 3D printing…

Statistics show that 26 million people suffer from heart failure in the world and there is a prevalent lack of heart donors. ETH Zurich makes use of 3D printing to create a silicone artificial heart.

CARMAT designs and develops an advanced artificial heart project, which would be a solution and a therapeutic alternative for patients suffering from end-stage biventricular heart failure. With AddUp’s 3D printing technology, CARMAT’s surgeons will be able to optimize anatomical interfaces leading to enhanced anatomical compatibility and surgical comfort on the one hand; on the other hand, to reduce a great number of components, therefore better secure the device’s assembly.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!