Machine manufacturer GPAINNOVA has added another post-processing system for additive manufacturing to its portfolio: the DLyte Desktop PRO machine. If you are a regular reader of 3D ADEPT Media, then you certainly know that the Spanish manufacturer is an expert in dry electropolishing technology. Its solutions are found in AM Solutions test center for post-processing of 3D printed parts andin companies’ facilities across key vertical industries – the latest we have in mind being the TEAMZIEREIS GmbH milling center.

Anyway, GPAINNOVA says this solution would be the first one of its kind to be released on the market. The ultra-compact dry electropolishing machine aims to “improve the work environment of thousands of small workshops and laboratories by replacing traditional hand polishing and hazardous materials with a safer option”.

GPAINNOVA has ensured that users benefit from three advantages: enhanced productivity (the machine would be “up to 10 times faster than any other equipment” according to the manufacturer), user-friendliness since itdoes not require a special pre-existing electrical or compressed air installation as well as the lowest possible maintenance cost.

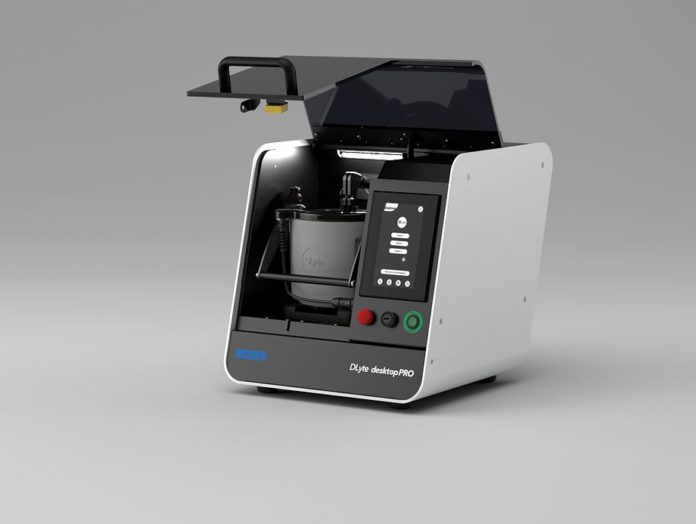

Based on the advantages of the existing DLyte solution, the small machine (dimensions: 450 x 521 x 471 mm), the machine works with an intuitive software which does not require from the engineer to have specific knowledge.

Due to the DryLyte technology performance, the plug-and-play system would guarantee minimal material removal, geometry preservation and a brilliant shine in every single metal piece. GPAINNOVA explains that its automated surface finishing help to achieve certain uniformity between batches and parts, this way, 3D printed parts can always meet the specifications required.

As far as utilization is concerned, users who are already equipped with a DLyte solution will realize that this latest solution works like the other equipment of the manufacturer. “First, a 3-liter container filled of solid electrolyte is placed in the machine in less than a minute. Then, the parts to be polished are clamped onto the holder finger, and placed into the equipment. Finally, the customer selects a program according to their needs. Once the fully automated cycle of 50-60 minutes is over, the metal piece is ready”, a press communication outlines.

Compatible with polishing cobalt-chrome (CoCr), titanium and stainless steel, the machine can process other metals such as copper, brass, nickel alloys, aluminum and hard metals with an optional software upgrade.

It is also worth mentioning that thanks to the machine’s automated process, operators are protected from exposure to hazardous particles during the “smooth and silent operation”. The manufacturer confirms that the consumables used are safe and clean, without hazards of chemical liquid waste or dust during the process and handling.

While we can’t wait to have a first real look and hands-on experience of the DLyte Desktop PRO machine, GPAINNOVA welcomes those who would like a first virtual look at the machine to join its online event, on May 20.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com