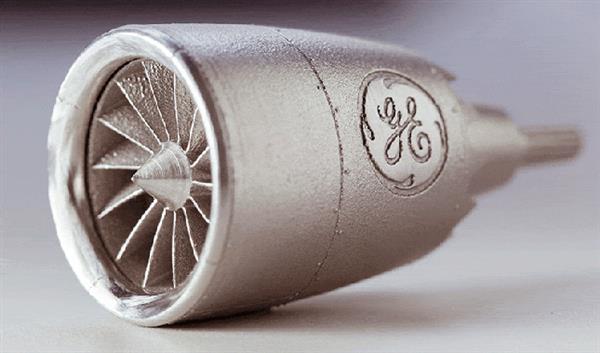

The 3D printing industry is a key part of GE’s investments on the EU market. With a contribution of € 100 million ($ 109million USD), the company just acquired a production site in Lichtenfels (Germany).

This is far from being the first investment of the group. Last year, they invested $1.3 billion into Concept Laser and Arcam, respectively 3D printing firm and 3D printer manufacturer. With the production site and these acquisitions, GE stands as a global leading player in additive manufacturing. The multinational company wishes to exploit the potential of powder and electron-beam additive manufacturing, currently two of the five main 3D printing technologies. For GE Additive Chief Mohammad Ehteshami, “[their] goal is to get into all of the [five].”

When he is asked if this goal could be achieved with solely organic growth, Ehteshami’s answer is that “[they] are always studying organic and inorganic possibilities… Strategically, there are inorganic plays [they] would not be smart not to do.”

As for their vision of the future, GE’s next step would be to separate its additive manufacturing division from GE aviation. The GE Additive Chief mentioned the construction of the first 3D printing customer training and support centre in Munich: an estimation of € 15 million.