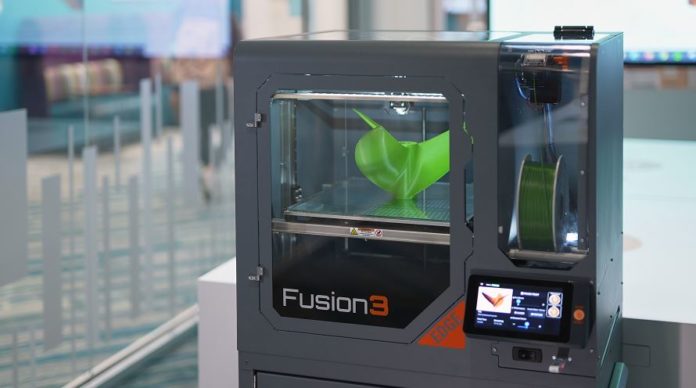

Machine manufacturer Fusion3 unveils a new professional 3D printer in its portfolio. Named EDGE, the new family member is priced at $6,999 and would provide several capabilities featured in expensive industrial 3D printers.

Based on FDM 3D printing like its predecessor (the F40), EDGE ambitions to deliver on all fronts: « best-in-class speed, large build volume, excellent surface quality, tight tolerances when printing hightemperature materials, ease of use, and durability for 24×7 operation », as per the words of the company.

The US-based manufacturer initially positioned itself on the AM market with the F410 3D printer, a high-performance 3D printer designed for commercial, education, government and military customers. Like this first machine, EDGE aims to serve the same industries and beyond.

« EDGE encapsulates Fusion3’s nine years of industry experience, accumulated feedback from customers, and our vision for the changes needed to drive mainstream, commercial adoption of FDM 3D printing, » says Kate Padgett, Fusion3 Founder & CTO. « With EDGE, we achieve astounding levels of speed, print quality, and durability through the upgrade of our F-Series Motion Control system with high-quality linear rails, the development of a new patentpending print head system for greater performance and customer serviceability, and the design and implementation of new control systems to create better user experiences and ensure successful print outcomes. »

Key specifications

Main features of the 3D printer are described as follows :

Exceptional Print Quality & Speed: Validated through millions of operating hours with thousands of customers, EDGE utilizes Fusion3’s “F-Series” platform, with upgraded motion control components including all-new linear rails, Gates 2GT2 belts, and specially tuned stepper motors. EDGE attains category leading print speed at standard print settings with tremendous improvements in print quality. EDGE enables unique features such as a new “Fast Mode” for printing certain materials at 200MM/sec using a .4MM print head.

ANVIL Print Head System: Fusion3’s patent-pending ANVIL print head system incorporates a surgical steel print tube instead of a traditional screw-in 3D printer nozzle. Use of a single print tube provides faster printing and is wearresistant for use with abrasive filaments such as carbon fiber or fiberglass-reinforced filament. In addition, the single tube design is more reliable, eliminating the chance of leakage. ANVIL is easier to maintain translating to lower operating cost.

Large, Enclosed, Heated Print Area: EDGE’s passively heated build area, which heats up to 70*C, can print parts as large as 14″ x14″ x14.5″ (1.64 cu ft), ensuring excellent print results when printing high-temperature, engineeringgrade materials such as ABS and Polycarbonate. Easy to Operate and Maintain: Successful print outcomes with EDGE start with its new bed leveling system.

EDGE comes standard with a ¼” (0.6 cm) aluminum tool plate print bed and a standard glass surface. This reference surface, coupled with our proprietary, ultra-light touch probe, enables EDGE’s mesh probe bed leveling system to ensure a near-perfect first layer for each print. In addition, EDGE incorporates a separate interface controller, powered by its own 64-bit ARM processor with 7″ touchscreen. This control system powers robust remote management capabilities and even reminds customers of recurring maintenance tasks. Future updates envision features including customer notifications and status updates via email and text.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com