With the advancements in fashion tech, we could wear in the future, clothes that might be able to monitor our health, manage our body temperature or communicate with smartphones.

To achieve this, scientists need to explore a way to print cost-effective intricate, flexible and durable circuits onto a variety of fabrics. A team of researchers has explored this route by developing a conductive 3D printing ink made of liquid metal droplets coated with alginate, a polymer derived from algae.

The problem with conventional electronics is that not only are they stiff but they withstand the twisting and stretching motions that clothing undergoes during typical daily activities. Gallium-based liquid metals (LMs) on the other hand, are inherently fluid and conductive, therefore an interesting fit as materials for flexible electronics. One of their disadvantages so far is that LMs don't stick well to fabrics, and their large surface tension causes them to ball up during 3D printing, rather than form continuous circuits.

That’s the reason why Yong He and colleagues wanted to develop a new type of conductive ink that could be 3D printed directly onto clothing in complex patterns.

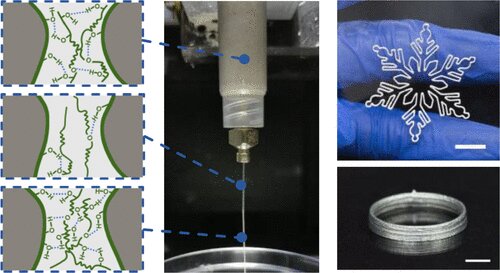

Graphical abstract. Credit: ACS Applied Materials & Interfaces (2022).

To make their ink, the researchers mixed LM and alginate. Stirring the solution and removing the excess liquid resulted in LM microdroplets coated with an alginate microgel shell. The ink was very thick until it was squeezed through a nozzle for 3D printing, which broke hydrogen bonds in the microgel and made it more fluid. Once the ink reached the fabric surface, the hydrogen bonds reformed, causing the printed pattern to maintain its shape. The team 3D printed the new ink onto a variety of surfaces, including paper, polyester fabrics, nonwoven fabrics and acrylic-based tape. Although the printed patterns were not initially conductive, the researchers activated them by stretching, pressing or freezing, which ruptured the dried alginate networks to connect the LM microdroplets.

The team 3D printed the new ink onto a variety of surfaces, including paper, polyester fabrics, nonwoven fabrics and acrylic-based tape. Although the printed patterns were not initially conductive, the researchers activated them by stretching, pressing or freezing, which ruptured the dried alginate networks to connect the LM microdroplets.

After activation, the printed circuits had excellent electrical conductivity and strain sensing properties. In addition, applying a small voltage to the ends of the circuit caused it to heat up, even in very cold temperatures.

To demonstrate the ink's capabilities, the team 3D printed a series of electronics onto commercial clothing. On a T-shirt, they printed a near-field communication tag that directed a smartphone placed nearby to open a web site. Other sensors printed on clothing monitored the motion of an elbow or knee joint. And a circuit powered by a small battery heated up the printed pattern to above 120 F in less than a minute.

The LM-alginate ink can be recycled by soaking the fabric in a weak sodium hydroxide solution, recovering fresh liquid metal for new applications.

The entire research can be read here.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com