With the goal of creating what is described as the “world’s largest 3D metal printed pressure” part, integrated oil and gas producer ExxonMobil Asia Pacific has signed a $190,000 manufacturing purchase orderwith metal 3D printing company AML3D that develops a proprietary WAM® technology.

According to AML3D, the sustainability of its process over traditional manufacturing and its ability to print commercial large-scale certifiable parts for use were key considerations in securing this contract.

WAM® production has significantly faster lead times to manufacture of around 12 weeks as opposed to a 12-month lead time for traditional manufacturing, allowing AML3D to address supply chain constraints that ExxonMobil was experiencing and to meet a September 2022 delivery deadline, AML3D states.

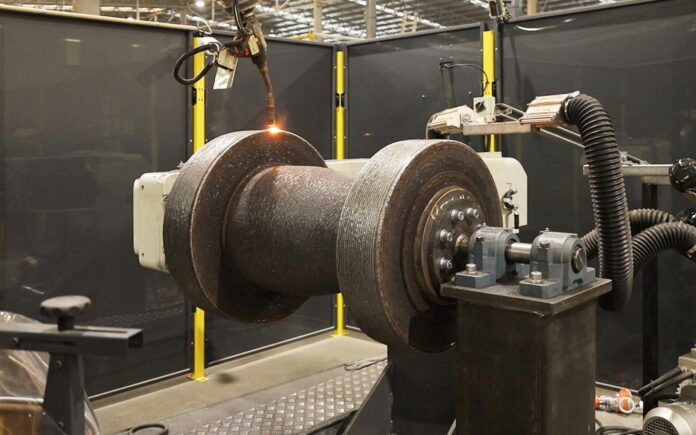

AML3D will use a high-strength wire feedstock of > 450 MPa yield strength to print the large pressure vessel. Testing will include hydrostatic pressure tests, full x-ray testing and visual inspection by 3rd party. The large printed vessel will be produced at the AML3D facility based in Adelaide with five of the eight installed ARCEMY® systems combined to construct the 8-tonne vessel. Capacity utilisation of the printing facility during this time will be up toward 75%.

The vessel manufacturing and testing will be verified for compliance to ASME VIII and will fall under AML3D’s Lloyd’s Register facility accreditation and certification processes and also follow the new global API 20S Standard for “Additively Manufactured Metallic Components for Oil & Gas components”.

Interestingly, so far, we’ve noted that most applications conducted in heavy industries like Oil and Gas or energy, are achieved using DED/ Wire-Arc AM processes. Remember the 3D printed lifting plugs produced by Vallourec, this 3D printed WAAM Clamp or these broken parts. Is it fair to say that WAAM might be an ideal production candidate for applications in this vertical industry?

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com