When people talk about technologies that could enable a net-zero future, water filtration rarely makes the list. Yet filtration membranes can consume up to 95% less energy than conventional thermal purification methods in desalination, for example. Beyond the obvious benefits (longer operating lifetimes and cleaner water), Evove is on a mission to cut both the cost and environmental impact of filtration and separation. Their use of additive manufacturing made me want to explore how.

Simply put, filtration membranes typically refer to physical sieving or barrier processes that separate particles or solutes from a fluid based on size. Used for water purification, wastewater treatment, desalination, food & beverage processing, or even harvesting of critical minerals, they belong to the larger category of membrane separations. This broader term, used in chemical engineering, includes all types of separations that use a semi-permeable membrane, not just filtration.

“Filtration membranes are at the heart of water purification: whether for industry, agriculture, or people. The problem is that most of today’s membranes are still manufactured using processes that date back to the 1960s. They’re essentially sheets of plastic dunked in chemicals to create random pores. The result is inconsistent performance: smaller pores clog quickly, while larger ones let unwanted elements through. That might be manageable in desalination, where excess salt isn’t harmful, but when you’re dealing with industrial discharge, you need absolute precision to stop heavy metals, PFAS, or acids from entering rivers and ecosystems. That’s where additive manufacturing comes into play: to bring a level of precision to membranes that conventional processes can’t achieve,” Andrew Walker, Chief Commercial Officer of Evove, told 3D ADEPT Media from the outset.

I met Walker last year at Formnext, where he was preaching the advantages of ceramic 3D printing to fabricate Separonics filter membranes. To get there, a lot happened behind the scenes.

The use of additive manufacturing for filtration membranes

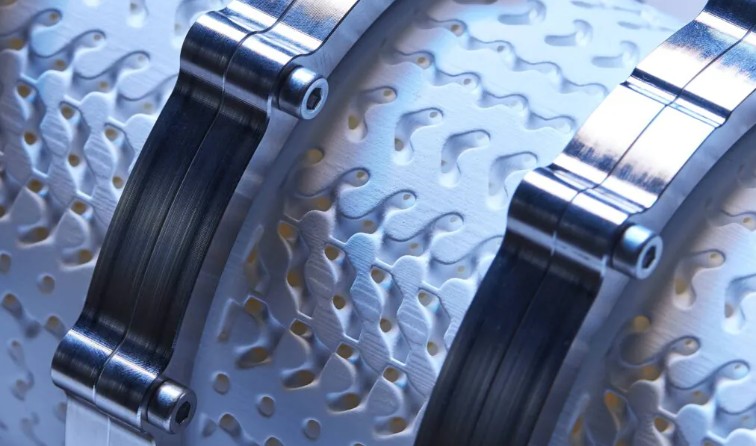

First and foremost, Evove™ is taking membranes to the next level by developing and commercializing two product lines: Enhance and SeparonicsR. The company has partnered with several ceramic 3D printing companies, including Lithoz, and demonstrated the lithography-based ceramic manufacturing (LCM)’s capabilities to produce the SeparonicsR filtration modules, hence the traction this product line has gained in the media. Thanks to the use of AM, the SeparonicsR product line can be customized for higher flux or better selectivity and therefore achieve a multifold performance boost.

Evove’s journey in ceramic 3D printing has not always been easy:

“We explored a variety of different printing processes in-house, and initially the most promising was reactive binder manufacturing: a special form of binder jetting that uses laser technology and a removable binding material. It overcomes issues with support structures and avoids the binder influencing the final product. However, when it came to scaling from R&D to commercialization, the process proved relatively expensive and difficult to scale up,” Walker explains.

At this stage, deeper conversations with several companies, including Lithoz, began. Given their background in ceramics, it turned out Lithoz was one of the partners with a viable alternative.

“We tried it out and it worked”, the CCO states. “From a water purification standpoint, ceramics are extremely benign; they won’t pollute drinking water. Materials like alumina oxide or silicon carbide are safe to use in applications such as filtering beer, fruit juices, or milk, where you need full confidence that nothing harmful will leach into the product. We chose ceramics because they’re healthy materials for filtration, and additive manufacturing allows us to localize production and address these challenges more effectively.”

Beyond the manufacturing stage, the critical stages lie in material science (resins) and post-processing (thermal treatment).

By fine-tuning the material formulation, they can engineer porosity and control pore size with precision. The subsequent debinding and sintering process is equally crucial, ensuring the filtration modules achieve the required performance. By reducing the sintering times and temperatures, thermal treatment can be more easily controlled to avoid imperfections in the product.

To test and validate AM-produced prototype designs and ensure reliability and performance, Walker explained they have their own printers and production line. He outlines:

“Using computational fluid dynamics, we design the Separonics ourselves, creating flow channels and microstructures tailored to different applications. For simple processes like desalination, the design can be straightforward, but for complex feeds containing heavy metals, acids, or bacteria, the internal structure needs to be more sophisticated. Essentially, our prototypes have now evolved into full-scale filtration modules. We print these prototypes in-house and then test them in our facility in the northwest of England, running either real or synthetic water feeds to validate performance before commercialization.”

Industries that can benefit from water treatment applications

This conversation with Walker opened my eyes to the wide range of industries that rely on filtration. At the top of their list, the company wants to focus on lithium, green hydrogen, data centre cooling, desalination—as mentioned in multiple examples above—food and beverage, as well as drinking water and industrial wastewater.

The expert details: “Desalination is relatively simple; you’re mostly just removing sodium from the water. But in food and beverage, the feed varies: strawberry juice behaves differently than blackcurrant, for example, because of the different solids and fibers. In data centers, the challenge is cooling water, which can contain organic matter, bacteria, algae, and metals. Semiconductor wastewater has silica, PFAS, and metals, requiring very different filtration properties. In lithium extraction, we deal with brines from geothermal or oilfield sources, often containing hydrocarbons, grit, and other solids. Each application demands a tailored membrane, and these five areas (desalination, food and beverage, data centers, semiconductors, and lithium extraction) are where we focus our efforts.”

In the vast majority of cases, ceramic materials, predominantly aluminum oxide, are effective for Separonic production. According to Walker, the choice of material is often driven more by unit economics than technical limitations. For certain niche applications, materials like silicon carbide may be required, though they come at a higher cost. Overall, aluminum oxide meets the needs of roughly 99% of applications.

The question is, is it possible to produce these filters competitively compared to conventional membranes on the marketplace? For Walker, the answer is “yes and no”:

“In simpler applications like desalination, membranes are essentially a commodity. New entrants from the Far East, particularly China, produce these at extremely low prices. They don’t perform as well as higher-quality products made in the U.S. or Japan, but they’re half the cost. The question is whether we can offer a more expensive filtration module with such high performance that it’s worth it for low-value applications. Today, the answer is probably not. However, in medium- and high-value applications, such as semiconductors, performance and reliability are critical. You want filters that last 20 years, not six months, and are able to “filter the unfilterable”, so it’s about choosing where you can truly add value.”

And just like that, Walker refocuses the debate on the potential of using additive manufacturing as an on-demand production capability.

The link with sustainability?

Water is directly linked to 60% of global GDP (WWF) and water scarcity affects us all. What if industrial process water were 30, 60, or even 100 percent easier to recycle? What if wastewater no longer generated any waste, but captured precious resources? What if filtration technologies could be manufactured locally, saving long-distance transport? We can’t guarantee the answers to these questions, but we do know that Evove’s activities contribute to solving them.

By using additive manufacturing, Separonics filters provide precise filtration, lower energy consumption, and greater resilience and longevity, achieving up to 80% less energy use with five times higher product yield, while recycling 80% more water and doubling resource extraction.

To me, that’s a strong point for any industry aiming to improve its filtration system sustainably.

*Walker’s statements have been edited for brevity and clarity. This content has been sponsored by Formnext.