3D Scanner manufacturer Evatronix SA has joined Universal Robots ecosystem and got UR+ certificate for its Heavy Duty Optima 3D scanner. The latter is therefore a device compatible with UR cobots. The result of the cooperation is a solution supporting the quality control process.

The collaboration between Evatronix and the expert in the field of collaborative robots (cobots) aims to improve the process of deploying automated quality control systems on production lines. UR+ certificate (a platform offering certified accessories for UR cobots) guarantees seamless implementation of the system, which reduced the time of return on investment.

The interaction of eviXscan 3D scanner with Universal Robots cobots is possible thanks to a unique extension (URCap) to the cobot software called eviXscan 3D scanner, which was developed by Evatronix. It enables the cobot to communicate with the eviXscan 3D Suite scanner software. This extension allows the scanning process to run under the collaborative robot’s control and program this process using the cobot’s teaching panel.

“The UR+ application kits with the eviXscan 3D Heavy Duty Optima scanner is an autonomic measuring unit capable of operating continuously in the production cycle. – Thanks to the specially designed URcap software, an operation of eviXscan 3D Heavy Duty Optima scanner on the cobot’s arm proceeds in a plug & play mode” – said Radosław Siwiec, Programmer, R&D 3D in Evatronix. – Programming robot paths is easy and does not require expertise. The user can select Single Scan or HDR mode and easily define scanning parameters for a series of scans.

It is also possible to use the full potential of eviXscan 3D Suite software and calling up predefined macro commands, such as post-processing of scans or export of 3D models to external quality control programs such as Design Control X or PolyWorks. The transfer of 3D models from the scanner to an external program is carried out automatically after the entire system has been configured accordingly. A report or OK/NOK information is generated for the checked object after a quality check is done. The aim of integration eviXscan 3D Heavy Duty Optima scanner with robot arm is to facilitate full automation of quality control based on 3D scanning technology on the production lines of Industry 4.0 (plug and produce concept).

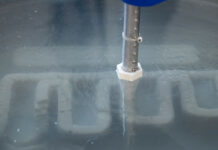

eviXscan 3D Heavy Duty Optima scanner uses blue LED structured light, which in combination with filters with appropriate spectral characteristics provides immunity to changing lighting conditions during measurement. The scanner achieves an accuracy of up to 0.0183 mm and provides a point density of 95 pt/mm². Heavy Duty Optima is designed for objects of the size 5 cm – 100 cm. The scanner can work in almost every environment – it is resistant to dust and moisture. Using a rotary table can further improve the scanning process.

“If you use the new UR+ certified eviXscan 3D scanner from Evatronix in combination with an UR robot, prototyping and scanning becomes easier than ever”, explains Irene Gallego, UR+ Implementation Engineer and continues. “The new scan product is empowered by the UR cobot experience in combination with the potential 3D processing software from Evatronix to be a “plug and produce” component for the UR+ ecosystem.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com