On this important 15th anniversary, EnvisionTEC unveils a new look for 3D printers powered by continuous Digital Light Manufacturing technology (cDLM).

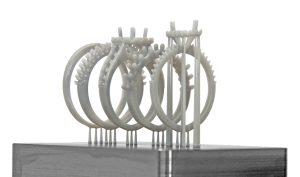

Jewellers and dentists are the professionals who will most likely be delighted to read this news.

In 15 minutes or less, the former can 3D print 5 to 7 custom designs for their customers using the Micro cDLM, enabling them to quickly close their sales.

The latter would print in 3D 12 dental crowns in 16 minutes in the E-Dent 400 material. They could also create five dental partials with delicate clasps in about 150 minutes, with a Z-resolution of 25 microns impressive.

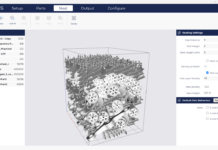

With a 3.54 x 1.97 x 3.94 in. “construction envelope, this super fast technology requires fewer supports during printing, which means less post-processing.

Al Siblani, CEO is proud of these 15 years of experience in 3D printing company and its steady progression:

« Continuous technology opens the door to amazing new materials that were previously not possible in 3D printing because of slower build speeds.

As photochemistry has evolved, some materials have come along that can deliver superior characteristics when cured by light. But some of these materials have a very short pot life, which means they have to be processed at rapid build speeds, much faster than conventional 3D printers using vat photopolymerization have typically moved. »

It is now certain that with the advent of 3D printing, new materials will still emerge, creating new opportunities in a wide range of industries.