Endurance Lasers has a great number of customers around the world. Today, we can share with you how our products bring an added-value to their business/activities:

Helge Dokken and the 20 watt laser (double beam)

I have had mine for roughly 6 months now, have not had time to use it as much as I would like, maybe 20 hours in total. I am not a professional user; I am using this for my hobby and not in a professional environment. From day one contacting George at Endurance the service and customer contact has been fantastic, any questions I have asked George has followed up on in a very good way.

After leaving it for about a week in the box I finally found some time to hook it up and do a bit of testing. Right now, I have only used one of the two lasers, the second one is not yet tested or used.

My plan was to use one configured for cutting and one for engraving, but have not found time to set this up yet. The lasers come ready to use with connectors on both the laser and control box, so setup is quick and easy. I have an X-Carve CNC, I have configured for use with my laser, so after hooking it up on that I was ready to fire it all up for a test run. And man, this thing has a lot of power, I got a bit WOW 😊

Regards a happy customer, Helge Dokken

How Markus Geßner has been using the 10 watt laser plus

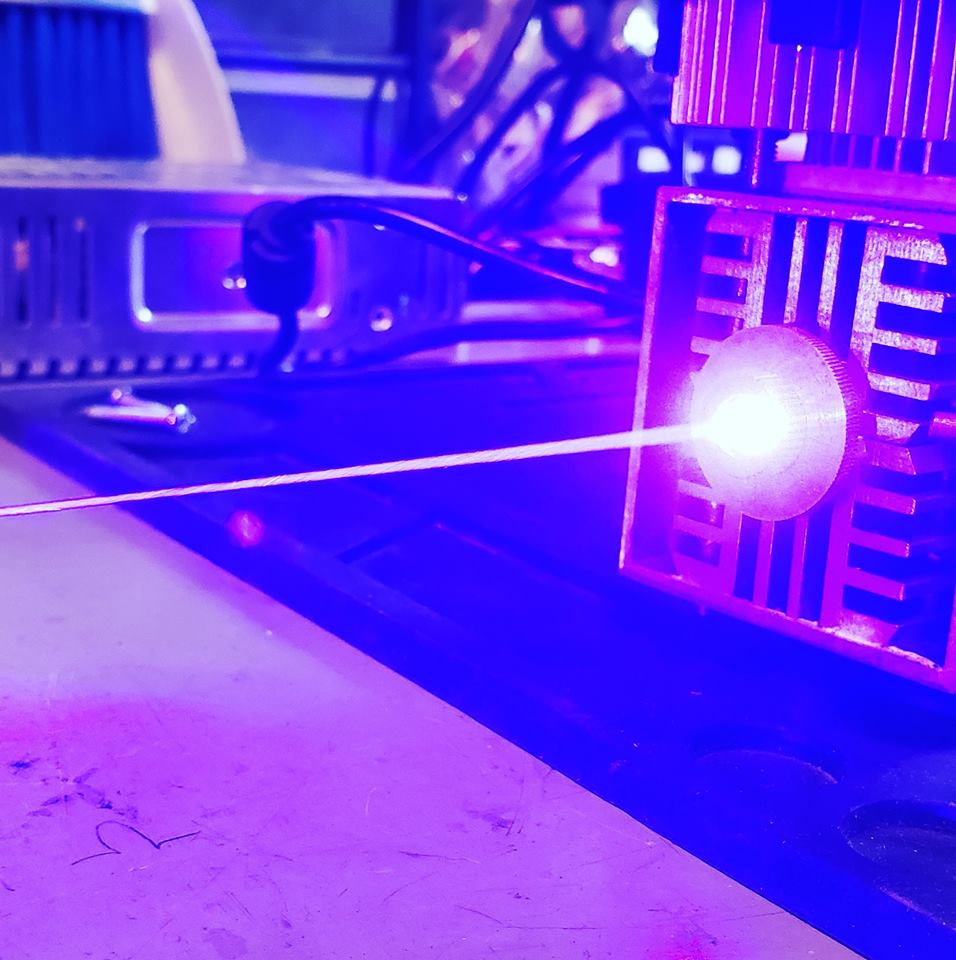

My name is Markus Geßner and I’m using Endurance Lasers since roundabout half of a year. I was searching for a little laser that could help me at work and in private things, but even strong enough to do engravings on metal. I had a few cheap lasers from China before but they were all living too short or working not at all.

So I decided to give the 10W+ Endurance Laser a try and I was surprised with a laser that simply makes everything I needed and wanted to do.

George Formitchev helped me with all that I was asking and it was a short way to mount the lasers to the machines. At the moment I’m using three 10W+ Endurance Lasers with two different 3D-printers and they do their job pretty well. I have done many different engravings on wood, plastics, eggshell, glass and metal and I know that there are many more (like leather,stone, ceramics etc.).

Depending on the laser power you can cut many materials with more or less speed while a 10W+ with the extra air assistance can cut thicker materials like 6mm plywood very nice.

Cutting coloured acrylic glass was a nice surprise because the Endurance Laser was able to cut 4mm with no traces of burning or melting the material.

I had to do many jobs with the lasers and they are fast in transforming the 3D-printer into a laser-machine and finish the work with precise quality and reliability. Even engravings over many hours worked very nice without any issues like on some China-lasers where they say not to use it longer than two hours.

In my last project I have used two lasers simultaneously on a T-Rex 3D printer like a twin laser.

All I had to do was to connect both of them to the printers mainboard, replace the two printheads from the T-Rex and fix them. That gave me the ability to do 100 engravings in half of the time.

And like on all other things – I use these lasers without any rest between. It’s a simple thing -set up the job and do it as many times as you want. The Endurance Laser is a working horse 🙂

Markus Geßner

Charlie Williams experience with 10-watt laser

I have started my business with Endurance laser.

My name is Charlie Williams and I live in Albany, NY. About 2 years ago I saw an article online about a DIY laser engraver build and I had to try it. I built my first CNC laser engraver using a cheap Chinese 5W laser. Over the first year I started getting a lot of orders and realized my cheap Chinese laser was just too underpowered and too slow to keep up with the orders. I then started researching higher quality lasers when I found Endurance Lasers. I read reviews and watched all the videos posted on the Endurance website. I had a lot of questions and George was quick to answer them all for me. I felt very comfortable making my purchase of a 10 Watt Endurance Laser.

When I received the laser it was simple to setup with my current Arduino board. I built a faster and larger gantry to mount the laser to. With the higher-powered laser and the TTL control board I was instantly making higher quality designs at a much faster speed. Within a few short days I was making detailed photographs as well as cutting through ¼ inch birch plywood.

Since I began using the Endurance Laser my Etsy business more than doubled and I now have my own website that I sell my products on White Lotus Wood’s website. I also have been getting a lot of followers on our Instagram Page @Whitelotuswood. Another thing I love about Endurance is the community of people that use the lasers. The Endurance Facebook page has been a great resource for design inspiration as well as getting answers to all my questions.

Charlie Williams

White Lotus Wood

For further information about Endurance Lasers, check out our website!