Home =

Cold Spray - search results

If you're not happy with the results, please do another search

Meet VRC, a newcomer introducing Dragonfly Cold Spray Additive Manufacturing for in-field repairs

A new company popped up on our radar this morning: VRC Metal Systems (aka VRC). Headquartered in South Dakota, USA, the company introduces a Cold Additive Manufacturing solution designed for in-field repairs. Named Dragonfly...

Woodside Energy to leverage cold spray 3D printing on offshore gas platform

As part of an oil and gas project, Woodside Energy, a service provider to the oil and gas industry, will rely on a Titomic D523 System to combat corrosion in the Indian Ocean, near...

Phase3D to develop a quality inspection system for cold spray Additive Manufacturing

Phase3D, previously known as Additive Monitoring Systems, has been awarded a 2-year $1.25 million contract from the Air Force Research Lab to develop a quality inspection system for cold spray AM (CSAM).

The company that...

SPEE3D to develop SUBSAFE manufacturing materials with Cold Spray Additive Manufacturing

The US Navy has chosen metal AM company SPEE3D to develop materials as a part of a Naval Sea Systems Command (NAVSEA) project related to Expeditionary Maintenance and Sustainment that achieve Submarine Safety Program...

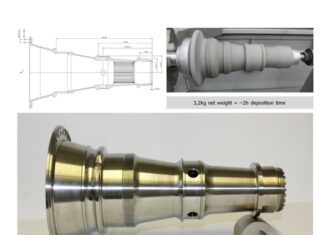

Impact Innovations GmbH develops a Cold Spray Additive Manufacturing (CSAM) process for Ti-6Al-4V

Remember this exclusive feature on Cold Spray Additive Manufacturing (CSAM)? One of the reasons why the process is an interesting production candidate is that since there is no heat, operators can easily explore the...

The importance of Cold Spray 3D Printing Technique in a Battlefield

The U.S. Army Combat Capabilities Development Command Army Research Laboratory (CCDC-ARL) has awarded $25 million to Worcester Polytechnic Institute (WPI) to advance a 3D printing technique called cold spray that is used to repair...

How to manufacture magnets using cold spray additive manufacturing?

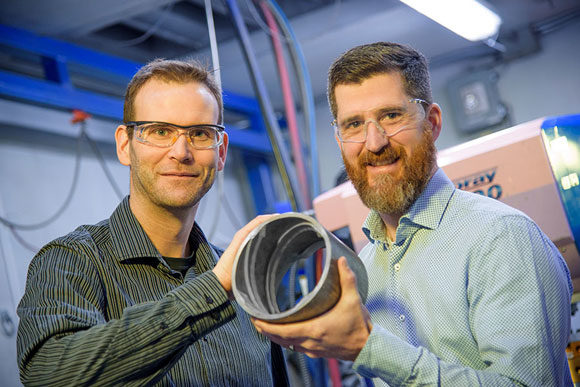

The National Research Council of Canada (NRC) developed a new process of fabricating magnets for electric motors without assembly. The fabrication process involves the use of cold spray additive manufacturing technique. The research has...

When DED metal 3D printing works for the French Navy

In sectors such as defense, laser powder bed fusion is not always the first Additive Manufacturing technology that comes to mind, especially for the creation and repair of metal parts. After Cold Spray Additive...

RusselSmith firmly positions itself as an AM reseller in West Africa, partners with SPEE3D

RusselSmith, an organization qualified by the Nigerian Upstream Petroleum Regulatory Commission (NUPRC) to deploy industrial non-metallic additive manufacturing solutions in the oil and gas industry, and the current unique African company member of AMGTA,...

First look at SPEE3D’s latest metal 3D printer: “TITANSPEE3D”

On the heels of the launch of its on-site metal AM solution, SPEE3D announces the launch of a large-format metal 3D printer. Named TitanSPEE3D, the new 3D printer would provide high design freedom and...