Eaton to Supply 3D Printed parts to Aerospace Industrial Development Corporation

Power management company Eaton will leverage additive manufacturing for the production of the aluminum housing and valve for the ram air valve assembly. The part will be used by the Aerospace Industrial Development Corporation’s (AIDC) Advanced Jet Trainer.

By leveraging additive manufacturing processes, Eaton reduced the development time by 75 percent while providing additional performance benefits for the customer.

A total of 22 parts were consolidated into two printed parts, reducing assembly time and eliminating potential leak paths through seals and threaded joints. The use of additive manufacturing also reduced part weight.

“We recognized the valuable role additive manufacturing could play in meeting the compressed timeline necessary for this program as well as offering a superior solution for this assembly. AIDC has been an excellent partner in the development effort,” said Nanda Kumar, president, Aerospace Group, Eaton. “We see additive technologies as a growing opportunity that will continue to strengthen Eaton’s competitive advantage. We look forward to leveraging our materials knowledge and process expertise to develop a pipeline of applications to deliver cost, performance and lead time benefits for future Aerospace Industrial Development Corporation programs.”

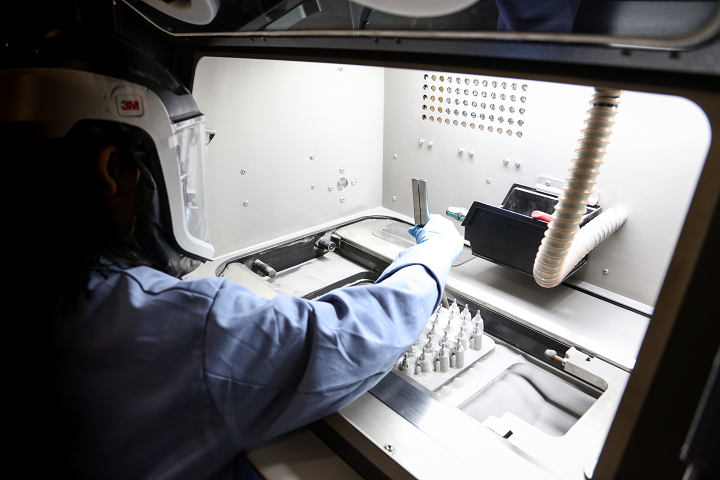

Under terms of the agreement, Eaton will supply the ram air scoop beginning in 2019. The parts will be produced at Eaton’s AS9100 certified Additive Manufacturing Center of Excellence and assembled at Eaton’s aerospace manufacturing site in Los Angeles, California. The delivery of this flight hardware represents another significant step forward in Eaton’s additive manufacturing program and is Eaton’s first military flight hardware application for aluminum laser powder bed fusion (Al L-PBF).

Featured image: Avio Aero – You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com