Since its very first steps on the market, Dyndrite – A developer of the GPU-accelerated computation engine, has been a true advocate of “open manufacturing”. In an “open Additive Manufacturing approach,” hardware and software solutions evolve together. 3D printer manufacturers open to this approach aim to meet the demand for better quality materials, more applications, and thus customization.

In a new partnership with 3D printer manufacturer Nikon SLM Solutions, Dyndrite underscores the importance of this approach. As part of this partnership, Dyndrite’s LPBF Pro software will be integrated into Nikon SLM Solutions’ metal 3D printing portfolio. These 3D printers include the NXG series, the SLM®125, SLM®280, and SLM®500 models.

What does this entail for Nikon SLM Solution users?

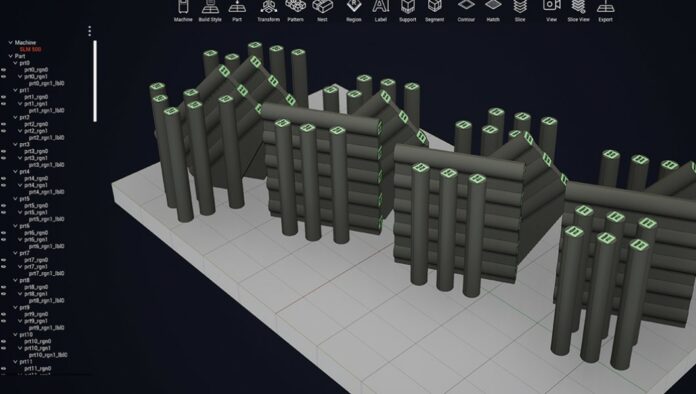

With this integration, users of Nikon SLM Solutions’ metal 3D printing will benefit from scalable slicing, low-angle support-free printing, optimized multi-laser coordination, and on-the-fly laser manipulation, enhancing productivity, and part quality for industrial-scale additive manufacturing.

Users could specifically focus on scalable computing, enhanced toolpath generation, advanced multilaser control, customization, and automation. By leveraging Nvidia GPU acceleration and multi-threaded CPU processing, Dyndrite enables rapid processing of complex geometries.

Dyndrite LPBF Pro provides advanced toolpath capabilities that seamlessly integrate with Nikon SLM’s single and multi-optic laser systems, optimizing scan paths to accelerate build rates and print previously impossible parts such as intricate geometries, such as small features, thin walls, domes, and cantilevers, improve part quality and surface finish and enable low-angle support-free builds, a press communication explains.

“Our collaboration with Nikon SLM Solutions represents a game-changer for the metal 3D printing industry that has been years in the making,” said Harshil Goel, CEO of Dyndrite. “Nikon SLM Solutions’ open architecture combined with Dyndrite’s compute and software capabilities delivers an unmatched solution for users seeking to dramatically increase build speed, improve part quality, or print without supports. We look forward to the array of new parts and part economics fundamentally enabled due to our combined solution.”

Industry experts who have already benefitted from this combined solution testify to the capabilities of Dyndrite’s software for manufacturing industrial parts.

Through his company, Rob Higham, CEO of Additive Manufacturing Services (AMS) Ltd, has been working for over 6 years with aerospace, space, and motorsport companies to push the boundaries of what’s possible in LPBF. “Within two days of using Dyndrite, we were able to print a thin-walled heat exchanger that, for over 18 months others attempted and failed to print – such an achievement speaks for itself,” he said.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.