The Additive Manufacturing Users Group (AMUG), set to be held from March 19th to 23rd at Hilton Chicago, in the US, has announced the recipients of its scholarship program, which ambitions to give educators/students access to the additive manufacturing community in an immersive way.

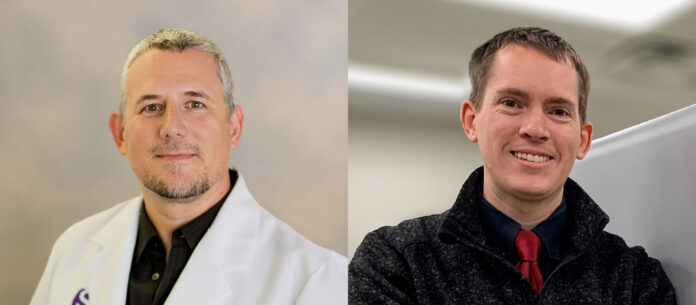

Dr. Les Kalman, Assistant Professor in restorative dentistry at Western University (London, Ontario, Canada), has been awarded the Randy Stevens Scholarship for educators in additive manufacturing. And Brent Griffith, P.E., who is pursuing a Master of Engineering in Additive Manufacturing and Design through Penn State University (State College, Pennsylvania), has been awarded the Guy E. Bourdeau Scholarship for students in additive manufacturing.

As scholarship recipients, Kalman and Griffith will attend the AMUG Conference, where they will engage with additive manufacturing users. They will take the stage to present their work on Monday, March 20, 2023. The AMUG Conference will be held in Chicago, Illinois, from March 19-23, 2023.

The scholarships recognize students and educators demonstrating passion and vision for additive manufacturing to advance education and industry. Rajeev Kulkarni, Chair of the AMUG Scholarship Committee, said, “Both of our scholarship winners exemplified a passion for additive manufacturing that was triggered many years ago but has not waned. Beyond that, the committee recognized their visions of changing how things are done coupled with diligence to make the changes a reality.”

Kalman and Griffith also empower others to change the world through their mentorship efforts, Kulkarni noted.

Kulkarni continued, “This year, we reviewed an almost record number of submissions. We were impressed with the elevated quality of the work. With every passing year, it is becoming increasingly difficult to pick the top scholarship recipients, which indicates the progress made by the additive manufacturing industry.”

Brent Griffith’s passion for additive manufacturing was ignited during his undergraduate studies when he received a 3D printer kit as an early graduation gift. Years later, he elected to further his additive manufacturing expertise by pursuing a master’s degree through Penn State while working at Labconco Corporation, where he manages the company’s additive manufacturing program.

Brandon Gray, Labconco’s VP of Engineering, said, “Brent has turned our world upside down, and we are so much better for it. He has done (and continues to do) an amazing job identifying innovative additive manufacturing solutions to add value to our business. He has demonstrated thought leadership in the field of additive manufacturing.”

Griffith’s research through Penn State focuses on the health and safety issues resulting from printer emissions. He said, “My hope is to contribute to existing research and help develop or add to the development of standards regarding the safety of printer operations. Ensuring that the printing process is safe in the long term for operators is important for the future of additive manufacturing.”

Griffith also makes the time to actively mentor and teach youth groups about additive manufacturing and its applications. He said, “I have taken every opportunity to use additive manufacturing to teach and help kids learn either directly or indirectly about the technology. Kids, especially younger kids, are unique in that they don’t yet have enough experience to fully grasp what is and isn’t possible, which I have found results in a high level of creativity. When you can help pair that level of creativity with a technology like additive manufacturing, you get to witness some really inspiring things happen.”

Dr. Les Kalman is an Assistant Professor at Western University, where he teaches and conducts research. He said, “In all of my teachings, I try to focus on improving the clinical experience through accuracy, efficiency, or communication. That is why 3D printing has become an important component in my teaching.”

Kalman has developed and instructed novel digital dentistry courses, some of which employ an experiential learning hands-on program with digital scanning, CAD/CAM, and 3D printing. These courses educate students and dentists on the advantages of 3D printing and its importance in patient care. Course development leveraged collaboration between industry and academia.

On the research side, Kalman stated, “I am currently involved in research that I feel is pushing and advancing the boundaries of 3D printing and additive manufacturing in dentistry. As a medical (dental) device researcher, additive manufacturing has provided an avenue to fabricate complex geometries and devices that were not previously possible.”

Kalman’s interest in attending the AMUG Conference stems from the many challenges and limitations that researchers face in the current climate. By attending the conference, he hopes to increase collaborative partnerships, benefit from conversations with those outside of dentistry, gain awareness of funding possibilities, and receive technology updates.

In testimony of his work, Dr. Yara Hosein, former Director of Operations at ADEISS, said, “I have always found Dr. Kalman to be a passionate professor and researcher, innovative in his development of ideas related to the field of dentistry. He possesses research experience, teaching expertise, and an inquisitive and invested interest in the future of additive manufacturing for the dental industry.”

The Guy E. Bourdeau Scholarship—founded by Guy’s wife, Renee Bourdeau, and financially supported by Cimquest, Inc. since 2019—is awarded annually to one college student. The Randy Stevens Scholarship—founded and financially supported by Randy’s former employer, In’Tech Industries—is awarded annually to one educator focusing on additive manufacturing.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com