Dassault Systèmes unveils SOLIDWORKS 2020, the latest release of its portfolio of 3D design and engineering applications. For several years now, companies and people across various industries have been able to benefit from sustainable solutions via the 3DEXPERIENCE platform.

Every year since its launch, Dassault Systèmes unveils upgrades that will enable million of users to accelerate and improve product development. In 2018 for instance, the company enabled to optimize designs for AM via 3DXpert™; last year other improvements have been noticed at the design level to reduce time-to-market.

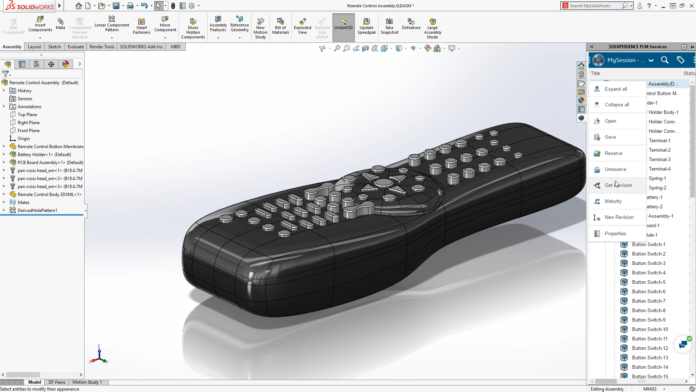

With SOLIDWORKS 2020, some of the enhancements include a better system performance in users’ daily operations, and an extension of their design to manufacturing ecosystem from the desktop to the cloud with seamless connection to the 3DEXPERIENCE platform.

Oher improvements include a more complete electronics design and data management, a new detailing mode and graphics acceleration for drawings as well as new capabilities to make part flexible.

As far as the new detailing mode and graphics acceleration for drawings is concerned, users could open their drawing in a matter of seconds while maintaining the ability to add and edit annotations within the drawing. Detailing mode is especially useful if users need to make minor edits to drawings of large assemblies or drawings with many sheets, configurations, or resource-intensive views.

The new capability to make part flexible allows users to display the same part in different conditions in the same assembly. For example, the same spring exists twice in the same assembly, but in two different conditions – compressed and not compressed. Make Part Flexible is useful in a variety of design applications such as springs, bellows, hinges, o-rings and just about any part that can flex or change condition.

“We aren’t just bringing powerful new capabilities to the SOLIDWORKS portfolio everybody knows and loves, but also extending it to the cloud through the 3DEXPERIENCE platform, the only holistic digital experience platform in the world. We’ve built a bridge to our platform-based portfolio, empowering our users to take advantage of 3DEXPERIENCE.WORKS offerings,” said Gian Paolo Bassi, CEO, SOLIDWORKS, Dassault Systèmes. “This gives organizations the environment and the applications to truly embrace the Industry Renaissance and its spirit of discovery for new ways of inventing, innovating, collaborating and producing.”

“Since 2002, Omax has used SOLIDWORKS applications to design every part of the fastest and most precise waterjet cutting technology in the industry,” said Eric A. Beatty, Senior Mechanical Designer, Omax Corporation. “Omax will continue to innovate and develop its waterjet machines and accessories with SOLIDWORKS 2020, which offers game-changing power, performance, and collaboration in the field by opening up access to the value creation process to everyone, everywhere, on any device.”

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media. For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com