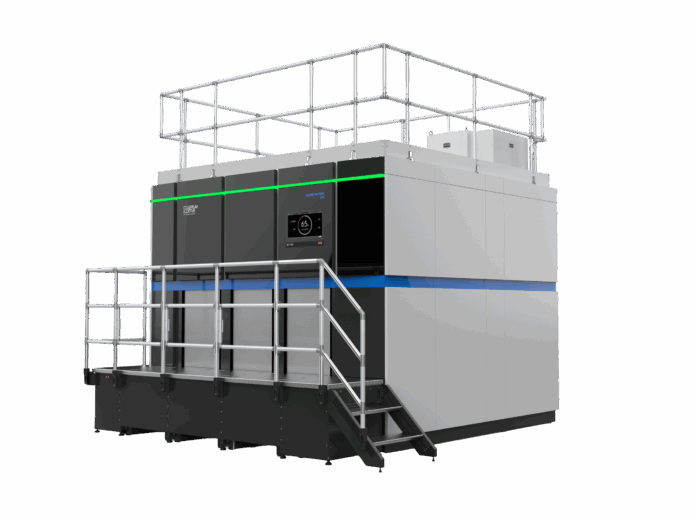

Colibrium Additive, a GE Aerospace company, is putting a new laser powder bed fusion in the spotlight at Formnext 2025: M Line 4 x 1 kW system. Already available for commercialization, the industrial 3D printer is built on the M Line 4 x 400W system, and is specifically designed to process non-reactive materials.

The new M Line 4 × 1 kW system already comes with parameter sets for CoCr and Ni718, with more materials currently in development. Parameters from the existing M Line 4 × 400 W platform are fully compatible with the 4 × 1 kW version, ensuring no loss in part quality. All parameter settings are fully accessible and editable via the standard WRX3 software suite, which also provides open access to sensor data and other operational data streams through an OPC/UA interface.

According to Colibrium Additive, the new version of the 3D printer helps to combine high-quality printing for certain areas of complex, sensitive engine components with high-productivity printing in the less demanding areas of the same component.

“The M Line 4 x 1kW system allows manufacturers to accelerate productivity without sacrificing quality,” said Philipp Schumann, product manager – M Line at Colibrium Additive. “It meets the rising demand, especially in highly regulated industries, for faster, more cost-effective production by combining precision where it matters most with efficiency across the rest of the part,” he added.

Key technical specifications

By using the M Line 4 x 1 kW, aerospace, defense, and other demanding industries, looking for a cost-efficient path to producing complex, high specification, regulated parts will benefit from:

- A 2.5x higher laser power

- A 500(x) x 500(y) x400(z) mm build volume

- 4 x 1kW IPG lasers (Beam power)

- Modular architecture with separate Laser Processing System (LPS) and Material Handling Station (MHS) units.

- Reduced manual intervention for tasks such as powder supply and powder extraction.

- Minimized stoppage times through automated, centrally controlled operations.

- Scalable and flexible configuration for industrial-scale serial production.

- Significant time and cost savings enabled by continuous, uninterrupted production flow

We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.