Supernova signs a $2 million subcontract to 3D print military-grade energetic materials

Supernova, a company that specializes in the development of Viscous Lithography Manufacturing (VLM), signed a $2 million subcontract to 3D print military-grade energetic materials.

The...

US Army additively manufactures military drones

The 101st Airborne Division (Air Assault) within the US Army is exploring the use of different technologies to manufacture military drones. As you may...

Defense : ArmorSource unveils a 3D-printed helmet suspension system

Combat Helmets represent the first defense against head injury, but it only works when the right helmet is worn correctly for combat operations. For...

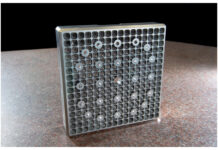

A 3D printed submarine component utilizing a 3D printed impeller to be installed on a U.S vessel

Curtiss-Wright’s EMS Division has delivered a submarine component with a 3D printed impeller that will be installed in a U.S. Navy vessel.

Curtiss-Wright Corporation provides engineered...

Mehler Protection enhances its ballistic protection solutions with 3D printing

Mehler Protection, a provider of protection and tactical-gear solutions for law enforcement and military forces, enhances its ballistic protection solutions with the launch of...

IperionX achieves major milestone with titanium furnace production

IperionX, an advanced titanium production technology company, has announced that the first production run of its Hydrogen Assisted Metallothermic Reduction (HAMR) furnaces at their...

Pratt & Whitney on its use of metal Additive Manufacturing for the development of military engines

Although it operates in a critical market often subject to confidentiality when it comes to revealing how it uses AM, we know Pratt &...

When DED metal 3D printing works for the French Navy

In sectors such as defense, laser powder bed fusion is not always the first Additive Manufacturing technology that comes to mind, especially for the...

Westinghouse 3D prints bottom nozzles to improve safety and efficiency in operating nuclear reactors

Westinghouse continues its journey in the use of AM within nuclear power plants by releasing recently developed applications. This time, the said application is...

Additive Talks: The use of AM in the nuclear industry and its hidden complexities

This third episode of Additive Talks was the continuation of a conversation that started two years ago during season two of Additive Talks. With...