Structuring data management in AM: Insights from BMW Group and NIST

A single build in additive manufacturing can generate hundreds of gigabytes, even terabytes, of melt pool data. And that’s just a fraction of what...

ONERA bets on 3DCeram’s MAT platform to advance AM of ultra-high-temperature ceramics

Launched in 2023, 3DCeram’s Multi Additive Technology (M.A.T) platform integrates multiple manufacturing processes (FFF, machining, extrusion/robocasting) within a single system. A recent collaboration with...

ASTM and CECIMO strengthen transatlantic ties in additive manufacturing

ASTM International and CECIMO — the European Association of Manufacturing Technologies representing AM Europe — have signed a Memorandum of Understanding (MoU) to strengthen...

Turning spoiled milk into 3D printing material? UW-Platteville professors show how.

A newly approved patent, titled “Development of Bio-Composite Materials for 3D Printing Using Milk Proteins,” has opened the door for spoiled milk to reduce...

Space Machines Company produces “Australia’s first” bimetal 3D printed rocket thruster

Space Machines Company (SMC), a startup specializing in mass-produced rapid response systems, completes the production of a bimetal rocket thruster using multi-material additive manufacturing...

Lithoz will 3D print ceramic heat exchanger for hydrogen-electric propulsion systems

Ceramic 3D printing company Lithoz is embarking on a new project funded by the EU: the TRIATHLON. The project brings together universities, industrial designers,...

A Honeywell-led consortium to explore how AI and additive manufacturing can improve aerospace technologies

A consortium led by Honeywell has received UK Government funding for a project that will explore how Additive Manufacturing (AM) can improve complex environmental...

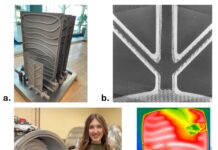

Thermwood and Purdue University merge predictive simulation with large-scale 3D printing

“First-time-right” production in Large Format Additive Manufacturing (LFAM) of advanced composite parts is like asking someone to marry you on the first date.

In LFAM,...

3D Systems receives FDA approval for custom 3D printing solution to repair damaged nerves

Additive Manufacturing company 3D Systems has partnered with TISSIUM, a French MedTech company, on the development of a bespoke 3D printing solution for the repair...

Cutting heat pipe weight by 50% with 3D Systems’ AM and new materials for space applications

Two projects funded by NASA shed light on the use of a material that is not always used in metal AM: nitinol.

This metal alloy...