Download the 2025 March/April edition of 3D ADEPT Mag

What if more accessibility leads to mass customization?

Each year, one edition of 3D ADEPT Mag goes beyond the usual news on product launches and...

ULT AG introduces new laser fume extraction system

ULT AG, an extraction and filtration technology expert, launches a new laser fume extraction system. Named LAS 260.1 MD.14, the extraction system would be...

ASTRO America & Plastometrex improve mechanical testing for defense AM

Plastometrex continues to position its mechanical testing solution as a viable solution for additive manufacturing (AM) applications in the defense industry. On the heels...

Post-processing | The use of 3D scanning in Additive Manufacturing

If you work in the engineering field, you are probably already familiar with 3D scanning, this process that consists in capturing a physical subject...

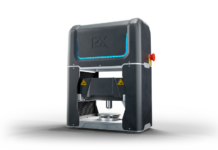

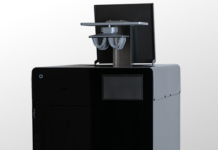

PostProcess Technologies unveils an automated all-in-one resin solution for 3D printed parts

For its latest solution, machine manufacturer Postprocess Technologies decided to integrate resin cleaning, rinsing, drying, and curing into a single compact system.

The new solution...

Rösler’s retrofit service enhances productivity without the need for significant capital outlay

Rösler, a machine manufacturer that specializes in surface preparation and surface finishing, recently launched a programme aimed at improving the performance, efficiency, and longevity...

toolcraft unveils a post-processing solution for metal 3D printed parts

Engineering company toolcraft AG has developed a dry ice blasting solution to remove support structures from metal 3D printed parts. The announcement follows its...

The Exploration Company bets on Solukon for the depowdering of rocket 3D printed parts

The Exploration Company, a European spacecraft manufacturer, has decided to rely on Solukon’s technology for the depowdering of its rocket parts. If you’re a...

Fieldmade and Plastometrex improve part confidence and safety for on-site metal 3D printing

Fieldmade, a provider of mobile and deployable additive manufacturing (AM) solutions, increasingly positions itself as a strong partner for defense organizations. Backed by Equinor,...

AMCM GmbH’s latest machine acquisition emphasizes the importance of niche solutions for AM

Spoiler alert: Solukon’s latest announcement is a teaser to one of our “end-of-year” reviews in the soon-to-be-released November/December edition of 3D ADEPT Mag. In...