High-precision motion control systems are important for the medical diagnostics and healthcare field, and additive manufacturing could enhance the accuracy and efficiency of these systems. The latest motion control system manufacturer to showcase this is ALIO Industries, a part of Allient. Since its inception in 2001, the US company has been helping many industries, specially the healthcare industry with its 20 years experience in developing high-precision motion control systems.

To improve digital pathology tools, the company has been relying on AM.

What is digital pathology?

Digital pathology is an urgent need of the medical and healthcare systems as they grapple with the pressure to be highly efficient and accurate in medical diagnosis amidst rising demands and challenges.

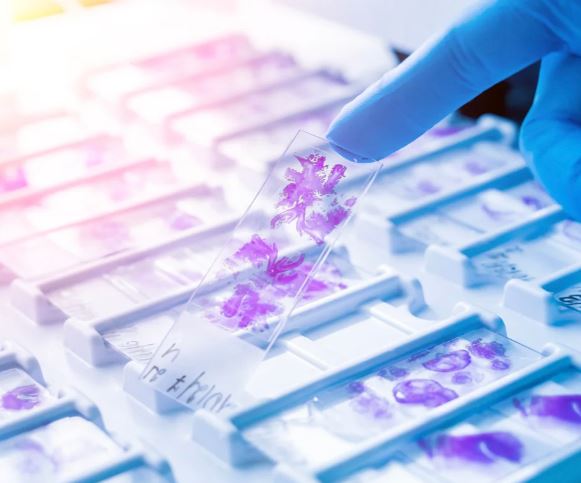

The digital pathology field involves the digitization of cell cultures and tissue samples for the development of advanced medical imaging and analytical techniques. It offers a transformative solution which allows pathologists to remotely examine and analyse specimens. This speeds up the diagnosis of diseases and facilitates global collaboration.

To realise the full potential of digital pathology, ultra-precise motion control systems are essential. The features and properties of many critical components of these motion control systems are enhanced by 3D-printed parts.

Earlier, ALIO Industries launched specific motion control systems to help deliver precise and coordinated movements of 3D printed components in AM machines. This helped in reducing bottlenecks like misalignment, over-extrusion, or insufficient material deposition in the 3D printing process.

The President of ALIO Industries, Bill Hennessey explained the role of motion control systems in digital pathology when he spoke of its ability to capture microscopic details of tissues.

“Digital pathology applications demand ultra-precise motion control systems for several compelling reasons. First and foremost, the microscopic examination of tissue samples requires movements that are accurate down to the sub-micron level. The slightest deviation in motion can compromise image quality and diagnostic accuracy, making ultra-precision an absolute necessity. ALIO’s motion control systems excel in delivering sub-micron precision and repeatability, ensuring that imaging devices can precisely position and capture microscopic details. Furthermore, in the field of digital pathology, environmental factors like vibration and electromagnetic interference can be detrimental to image quality. Motion systems must, therefore, be designed to minimize these disturbances, guaranteeing the clarity and reliability of the images produced”, revealed Hennessey.

Why is 3D printing important here?

Through the use of 3D printing, ALIO Industries ensures that its ultra-precision motion control systems have additional features like durability which enables it to fully integrate into the compact space and workflows pre-determined by the complex imaging system of the instrument. This enhances the overall efficiency and reliability of digital pathology.

Digital pathology OEMs need to invest their resources to develop which puts motion control systems in trusted hands. With this collaborative approach clinicians and researchers can leverage key advancements in digital pathology to provide fast, accurate and reliable diagnostic solutions to patients.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com