Two years after their official launch, machine manufacturer BCN3D introduces an updated version of its Epsilon 3D printers. The capabilities of the flagship version have helped industrials like Nissan and Saint-Gobain save time and costs in their production environment.

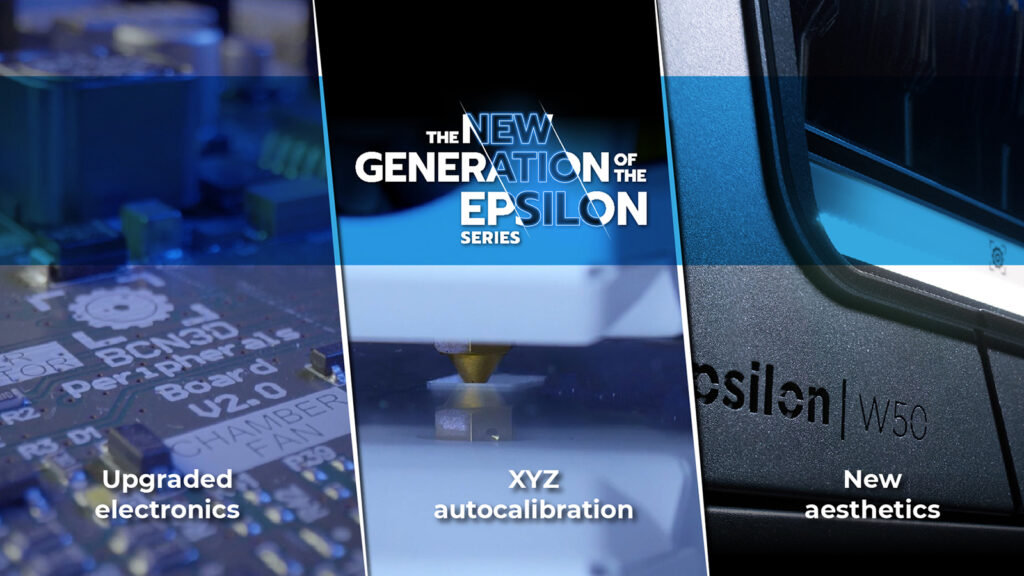

While the IDEX technology, the print volume, industry ready materials and the integration with the Smart Cabinet remain unchanged, the new version ambitions to improve other capabilities. This can be seen through a new and improved electronics, a local network access, new auto-calibration feature and a few Epsilon material bundles in terms of options.

As far as electronics is concerned, BCN3D has equipped the new Epsilon with a new ventilation system, new motor drivers, and new main board.

One feature highly anticipated by our customers, especially those in the corporate world, is local network access: an internal web server allows you to access it via its local IP address; send files, monitor, pause and cancel prints jobs remotely. This can also be enjoyed by owners of previous Epsilon versions after a firwmare update, the company says.

As for auto-calibration XYZ, this newly added feature can reduce the printing set-up time from 40 minutes to just 6 (that’s 85%). The manufacturer also explains that this technology takes away the user dependence on human criteria, reducing room for error and guaranteeing a correct first layer adhesion every time.

As for auto-calibration XYZ, this newly added feature can reduce the printing set-up time from 40 minutes to just 6 (that’s 85%). The manufacturer also explains that this technology takes away the user dependence on human criteria, reducing room for error and guaranteeing a correct first layer adhesion every time.

This calibration process is done by measuring multiple points to automatically adjust the printing surface height and (XY) offset between both nozzles. For 3D printers already equipped with BCN3D’ Independent Dual Extrusion System (IDEX), the XY alignment of the two toolheads should be taken into account. This is done through the use of a square located at the back of the printing surface. The toolheads use this small opening to touch the sides with the hotends, calculate their positioning on both the left and right axes, and subsequently calibrate the right offsets between them. This XY alignment ensures they are perfectly aligned and avoids any crossovers or shifting layers when printing in dual mode.

Lastly, the user can also rely on Epsilon material bundles to expand their printing horizons even further. The BCN3D Fiber Pack, including fiber-filled materials, adhesives, and specially designed hotends, is an all-in-one solution for equipping your parts with top mechanical properties. Or, for almost 100% stainless steel parts, the BCN3D Metal Pack is an upgrade that provides an office-friendly solution to obtain pieces with practically identical behavior to those from MIM or CNC, BCN3D concludes.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com