For some reasons, amid the wide range of metal 3D printing available on the market, Wire-Arc Additive Manufacturing (WAAM) is often a technology that is used by 3D printing service providers to deliver 3D printed parts.

We rarely heard that industrials directly install Wire and Arc Additive Manufacturing (WAAM) technologies onsite yet, that’s the case with Arcelor Mittal Ghent, a leading steel and mining company.

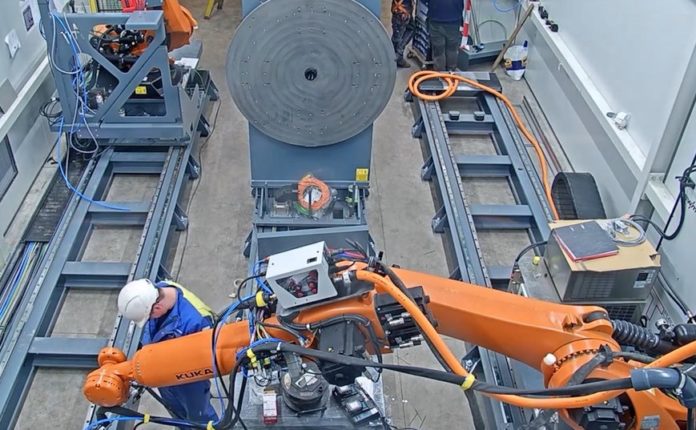

It’s been over 10 months that Actemium, a global company that advises, designs, builds and maintains industrial processes, installed the first WAAM technology for the Arcelor Mittal central workshop. In the AM industry, the company is mostly known for supplying equipment for processing metallic powders.

In this specific case, in order to reduce spare parts and resulting waste, the WAAM machine helps to repair broken parts or ‘print’ new spare parts.

“This way, the circular use of the materials will avoid the production of extra spare parts and transportation. WAAM makes it possible to repair parts that otherwise would be thrown away. WAAM, like other 3D printing techniques, can be used to produce unique pieces, small series, or prototypes. Parts with complex geometry or products consisting of multiple materials can be manufactured more efficiently by 3D printing compared to conventional processes. By using standard welding robots and specific software, WAAM can weld several kilos of material per hour, making the production of large parts cost-effective and quicker than other 3D printing techniques.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com