Bavaria and the world

With the global upheaval in political systems and markets and their impact on international supply chains, there is no better time for industrials, academia and authorities to sit down and discuss how they can join forces for the good of the AM industry. However, the challenge here lies in their ability to take actions that can benefit their region but also countries out of their sphere of expertise. Discussing this issue has been a major stake of the second day of AMTC.

If you are reading us for the first time, note that AMTC is a C-level conference dedicated to Additive Manufacturing. Hosted by Oerlikon and the Technical University of Munich (TUM), the event has become a platform that fosters the much-needed synergy that must exist between fundamental industry stakeholders, the ultimate goal being to enable AM to earn credibility as a viable manufacturing technology. That was discussed through various activities conducted on the first day of the event with a key focus on the start-up economy in the AM industry.

The welcome session of the second day was marked with inspiring talks of the members of the soon-to-be incorporated Bavarian AM Cluster, after the President of the Bavarian State, Ilse Aigner emphasized the role of authorities in technological progress and how within Bavarian politics, the commitment to impulse innovations is deeply rooted.

While he didn’t fail to mention the current challenges (social peace, energy, etc.) faced by European and American countries and the critical role China can play in addressing some of them, Thomas Hoffmann, President of the Technical University of Munich rapidly highlighted how industry stakeholders should remain attentive on issues they have the power to address: the gap that needs to be closed between academia across different regions, between academia and industry and the pivotal work that needs to be done in terms of research transfer.

Prof. Michael Süss, Executive Chairman of Oerlikon states the current time is essential to engage in cooperation within the industry, to transcend from a niche to a large-scale industry. Therefore, the question of where the AM industry is positioning itself as a driver of society rises as a relevant axis to consider for the next gatherings to come. For Prof. Süss, qualifications are one essential item to keep in the loop, as much of industries conservatism is based on the need to be 100% reliable to avoid any accidents.

Those introductory talks were followed by the signing ceremony that marked the launch of the Bavarian AM Cluster, created by Siemens, Audi, MTU, EOS, Linde, GE Additive, Oerlikon, and TUM – a signing that we covered here.

International cooperation: AM across the globe

Peter Koerte, Chief Technology and Strategy Officer at Siemens AG shared a very pragmatic approach to three main issues that impact the workflow from early design to manufacturing and how AM can play a key role to address them. These issues include climate change, conflict and the ongoing consequences of the Covid-19 pandemic. These challenges refocus the debate on the need to amplify cross-border cooperation between AM players. The ongoing pandemic, the Ukraine war and the climate crisis are issues that impact the AM ecosystem and the supply chain across vertical industries.

One way to address these problems is by applying a decentralized production, moving closer to sustainability goals. The resilience of the industry and the development of applications will ultimately contribute to driving AM industrialization and internationalization. To this, Francisco Betti, Head of Advanced Manufacturing/Member of the Executive Committee, World Economic Forum argued that visibility throughout continents is still needed. For Lionel Lim of the Singapore Economic Development Board on the other hand, we should recognize the major role of America and Europe as leaders but assure that Asia can feature more strongly in the future by taking inputs from these regions. One of the strengths of Singapore is its supportive government policies. As a matter of fact, that’s one of the reasons why Siemens established its Advance Manufacturing Transformation Centre in the region.

On the other hand, Dr. Nicholas Deliyanakis, Deputy Head of Unit, Industrial Technologies Strategy, DG Research & Innovation of the EU Commission highlighted the work of Europe in the commercialization of specific technologies such as AM. According to Deliyanakis, this commercialization has been fostered thanks to the European Institute of Technology (EIT) and the projects conducted to enhance the industrialization of AM. In this vein, EIT Manufacturing, an Innovation Community within EIT connects manufacturing players across Europe by enabling the development of infrastructure skills, and financing.

Research Focus: the much-needed frame to foster an international collaboration network

From a technology standpoint, the topics at the heart of R&D are often the same. Prof. Katrin Wudy for instance, a professor of Laser-based Additive Manufacturing at the Technical University of Munich is working on productivity, new AM materials and new applications. Wudy believes that academia also has a role to play in the search for solutions to supply chain issues and that role could be more tangible if they work hand in hand with industrial companies. Other topics of interest include process monitoring defect detection and its impact on AM efficiency throughout the pipeline.

“Sometimes, there is a problem that a company faces, and we have the capabilities to solve it. What may lack is the required financial resources to do so”, Prof. Markus Bambach, Professor for Advanced Manufacturing at ETH Zürich adds.

From a business standpoint, a look into the activities of R&D professionals across the globe reveals similarities and disparities in their working processes. To foster international collaboration between universities for example, opportunities for all students can also drive cooperation between regions that do not always have a balance in their funding system. Germany and Sweden may have similar funding processes for research but they are quite different from Switzerland.

For Prof. John Hart from the Massachusetts Institute of Technology, it should be about diversifying the potential sources of supporters. Indeed, both industry companies, the federal government and private foundations can materialize stronger collaboration. Those external stakeholders can help in a certain way to prevent the reaction to geopolitical events that define in many ways the timing for the industry to adapt to certain conditions.

A look at the vertical industries adopting AM technologies across regions

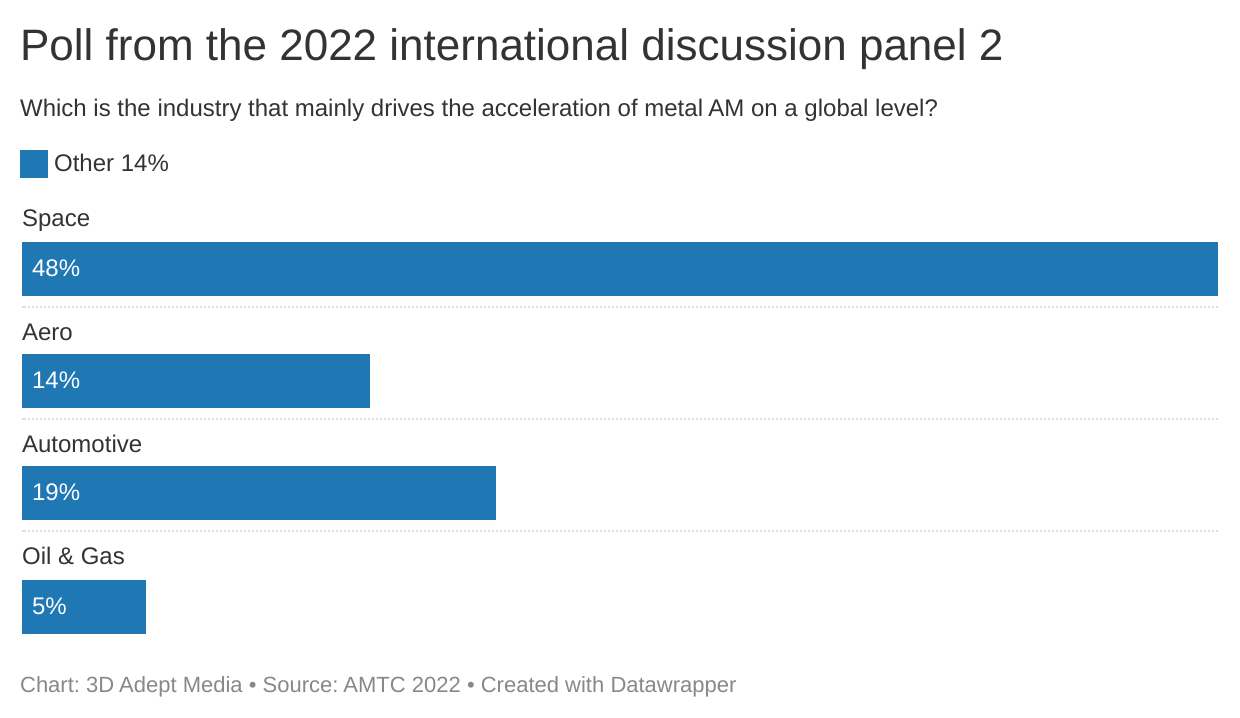

The panel discussion between Prof. Johannes Henrich Schleifenbaum, from RWTH Aachen and Prof. Christian Seidel, from the University of Applied Science Munich, highlighted perspectives from various vertical industries adopting AM technologies. Surprisingly, a discussion on the main industries that drive the acceleration of Metal AM at a global level reveals that the automotive industry is in 3rd place. Given the number of applications that are covered in the automotive industry, we would have placed this vertical at the top of this poll. Our thoughts have been confirmed by Prof. Seidel who explained that there is a gap between the industry reports and the numbers shown on the poll. Trending examples in the aerospace industry may bias what’s happening in automotive production. “The automotive industry is a market that can drive the benefits of AM in terms of mass production”, he adds.

While the healthcare industry is not part of this poll, one should note that organizations across Europe and USA are investing a lot of resources to drive AM applications in this sector. The thing is, AM still raises a debate on the series production of 3D printed implants and their incorporation into the body hence its absence from this poll.

Lastly, the panel shed light on the use of AM materials and their ability to help users to achieve sustainability goals. In this vein, multi-stakeholder collaboration should not only be about sharing knowledge, but also standardizing the use of materials so that the AM industry can reach its full potential. With the strong development of metal AM applications in the aerospace and healthcare sectors, it is increasingly important to think about standards that protect these innovations within specific regions while enabling them to be adopted on a global scale.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com