Ampower has recently provided an in-depth analysis on 3D printing in the automotive industry. The analysis lays emphasis on the production of metal components for sports cars.

The consultancy firm specialized in industrial additive manufacturing has precisely analyzed the production of an exhaust tail pipe blend of a sports car. The design optimization as well as the production stages are described in the study.

Overview of the study

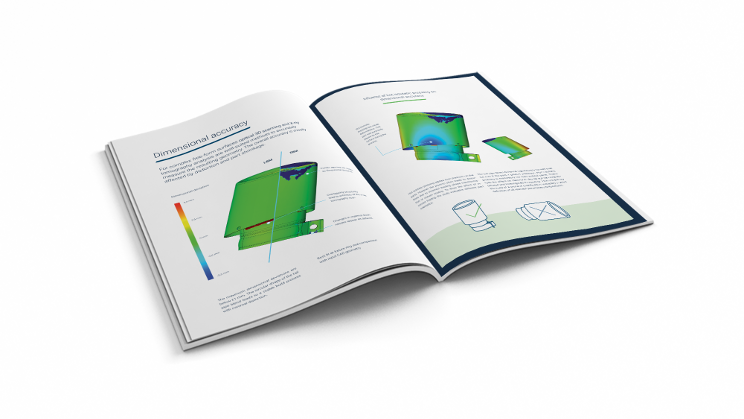

It should be noticed that a wide range of criteria enabled to examine the component. An x-ray analysis helped to determine the dimensional accuracy as well as identification of residual powder. Furthermore, experts looked both at the impact of Laser Beam Melting and Electron Beam Melting.

The two technologies show differences in terms of the surface quality. “By means of vibratory grinding and polishing, a surface roughness Ra of less than 0.1 μm is achieved in the case of the Laser Beam Melting component. In addition, the use of multi-laser machines makes the production of this component cheaper than Electron Beam Melting.”

The company explained that conventional tail pipe blends are manufactured by means of deep drawing tools, which can result in lead times of several months to a year. In contrast, 3D printing allows production within a few weeks until the component is ready-to-install. “In the course of ever shorter development cycles, valuable time can be saved. Due to the low number of sports cars, the process also becomes cheaper.”

The complete study might be read on Ampower’s website.

As far as 3D printing in the automotive industry is concerned, a case study dedicated to the manufacturing of a brake caliper may give you another approach of manufacturing in this area. The case study is available in the former issue of 3D Adept Mag (page 18).

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!