After a year marked by several contracts in the defense sector and the establishment of headquarters and manufacturing facility in the US, OEM AML3D taps into the US nuclear subs supply chain. The large format 3D printer manufacturer delivered tailpiece 3D-printed parts, valued at approximately A$156,000, for testing and for in-service trials on board a Virginia-Class nuclear submarine.

The Copper-Nickel component will deliver a step change in production efficiency and component quality for the U.S. Navy’s submarine industrial base.

The Virginia-Class submarine prototype tailpiece components were 3D metal printed in less than five weeks compared to an average 17-month lead-time via traditional manufacturing. Over the past two years, AML3D has partnered with the U.S.Navy’s Maritime Industrial Base (MIB) Program and BlueForge Alliance to meet emergent material readiness needs for U.S.submarines, and integrating metallic additive manufacturing as an alternative solution to support critical supply chain gaps and constraints.

AML3D’s contribution to support the AUKUS partnership has been recognized by the Deputy Prime Minister and Minister for Defence Richard Marles, who said, “Production of a U.S.Virginia-Class Submarine component in Australia is a great example that AUKUS is happening now, and demonstrates our commitment toward supporting the expansion of the trilateral industrial base. Australia’s Nuclear-Powered Submarine Program and the AUKUS partnership will provide incredible opportunities for Australia’s industry, and these opportunities have already started.”

This follows the U.S. Program Executive Office Attack Submarines, Admiral Jonathan Rucker’s noted contribution by AML3D to U.S.Navy efforts.

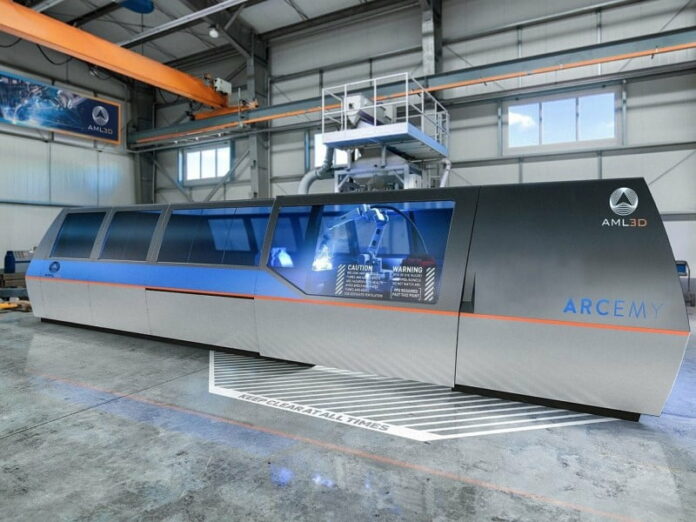

AML3D CEO Sean Ebert said: “AML3D has been working with the U.S. Navy and its partners for close to two years. In that time, we have created a successful model that includes cross-continental coordination, information sharing, and the deployment of our ARCEMY advanced 3D metal printing technology across a network of U.S. defense industry and academic experts. We have also completed several alloy testing and characterization programs including Copper-Nickel, which allows us to supply components to the U.S.Nuclear submarine program.”

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.