Advanced Family & Sports Podiatry is an Australian medical center that aims “to provide patients with sports injuries a state-of-the-art practice with the most modern equipment to improve their lower limb, foot and ankle health”.

To enhance its practice, the centre has decided to explore the capabilities of 3D printing technologies in the production of orthoses. First attempts with FDM and SLA did not provide satisfying results, especially in terms of desired mechanical strength.

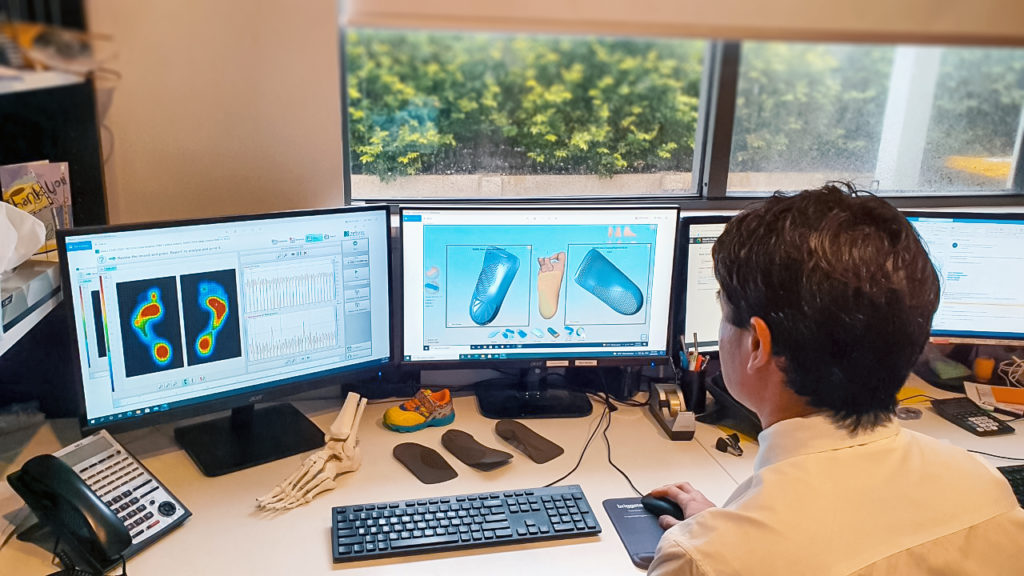

Mark Ireland, the owner and principal podiatrist of the centre, explains that in podiatry, 3D printed objects have to fulfill special requirements: «Our parts need to have a high degree of accuracy and can involve complex shapes to contour and help the foot and ankle function», Mark explains. «They also need to have some flexibility without shattering, and have a high heat deflection temperature to preserve the orthotics shape under stress.» Not to mention they should enable a low moisture absorption due to the environment such orthoses are commonly used in.

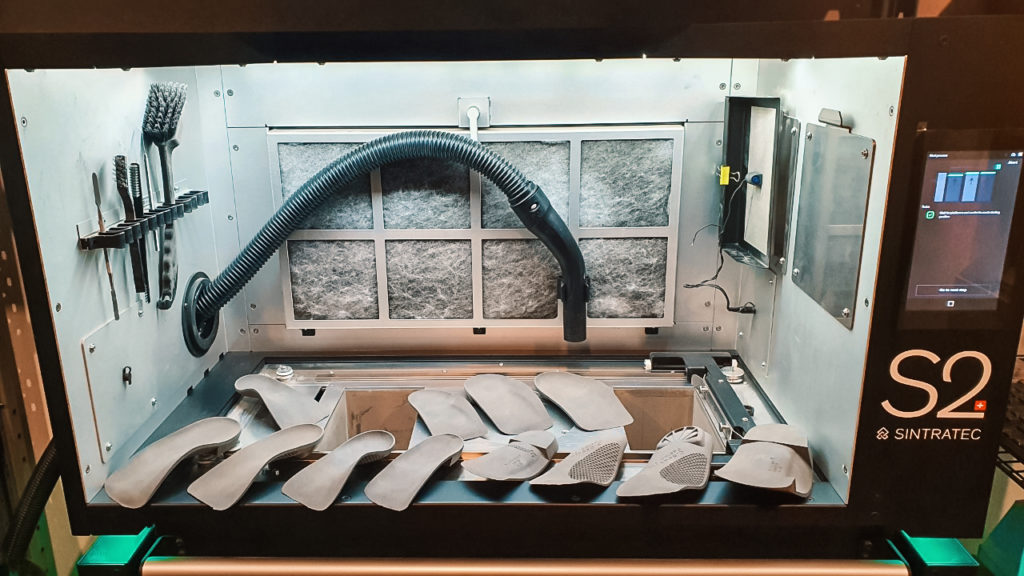

To meet these requirements Ireland and his team explored the use of Sintratec’s Selective Laser Sintering (SLS) process. The team decided to install the S2 system for these production needs. As a reminder, that’s a machine, the Swiss machine manufacturer unveiled three years ago at Formnext. Its modular system can be delivered in an all-in-one integrated and semi-automated processes of laser sintering, de-powdering, material preparation and post processing.

«The biggest advantage to us is the speed of production, accuracy of the build, unrestricted design freedom to test and push new shapes for the benefit of our clients», Ireland notes. Used for the production of custom and semi-customized foot orthoses, the team 3D prints their parts using a Sintratec PA12 nylon material.

«The materials fitted our requirements perfectly, the user interface ensured our staff were kept safe when handling the material during powder mixing and parts unpacking processes, and its price point is impossible to beat with the amount of technology on offer packed into a machine of such high quality», the owner points out.

As far as time is concerned, Sintratec reports that whereas patients previously had to wait up to two weeks for their orthoses, they are now able to receive a customized product within 24 hours.

Lastly, as we continuously explore the different medical applications that can be made possible using SLS 3D printing, one notes that orthoses are added to a range of applications that already includes the production of drugs and the production of special chairs for extension therapy.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com