“The perfect blend of affordability of a small metal printer with the versatility of a larger system”, Additive Industries says.

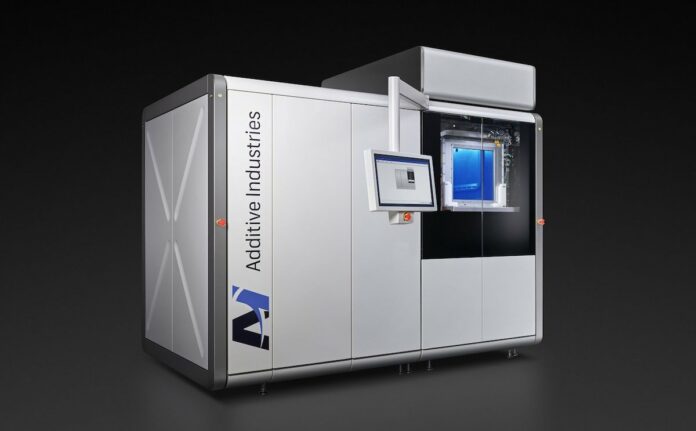

Dutch metal 3D printer manufacturer Additive Industries unveils this year at RAPID+TCT 2024 a new metal 3D printer. Named MetalFab 300 Flex, the 3D printer stands out from the crowd due to its ability to adapt build area depending on the user requirements. Expandable from 300x300x400mm to 420x420x400mm, the 3D printer is equipped with several automated features, from automated powder handling to laser calibration.

Mark Massey, CEO at Additive Industries: “At Additive Industries, we are proud to lead the way in making metal additive manufacturing more accessible and affordable. The MetalFab 300 Flex which is based on our proven metal PBF technology is designed to help our customers manage their technical and financial risk as they grow their AM business. It is specifically aimed at customers who need to be able to build both small and large parts but without incurring the upfront expense of a large printer.”

As costs remain a topic of debate for industries, the OEM believes that the 3D printer’s mid-range $730,000/€680,000 price point and subscription model would increase its accessibility among users, especially those in automotive, defence, oil and gas, semiconductor, and other industrial sectors.

If you’re familiar with Additive Industries’ technology, you may know that automotive giants as well as industrials across the space industry continuously bet on the company’ LPBF solution. With the MetalFab 300 Flex, the company will now target users who are looking to make a savvy investment in AM while affordably scaling production when time will allow. It’s the era of flexible manufacturing.

Other technical specifications include:

| Base specification | |

| Laser | 2 x 500W Yb-fiber Laser |

| Focus diameter | 110um |

| Optical calibrations | Inline automated laser-to-laser & focus |

| Accuracy / reproducibility | <0.05 mm |

| Layer thickness | 20-120 um |

| Machine size | 2.8 x 1.9 x 2.5 m |

| Machine weight | 5000 kg |

Read more in this dossier: Understanding the complexities and opportunities of Multi-Laser Additive Manufacturing

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com