“We’ve grown rapidly especially since our customers highly value our integrated and automated systems and we have developed a workflow that was seen as the industrial production standard in a short time by global companies like Volkswagen that share our vision.” Daan Kersten

Additive Industries keeps developing new strategies to foster the production of additive manufacturing applications. Six years after its launch, the company has proven itself in a wide range of sectors: aerospace, automotive, high tech equipment, food tech as well as oil & gas. The company is growing at fast pace and is partnering with leading companies from various industries around the world. It’s been a few years that we have been following the Netherlands-based manufacturer and today, Daan Kersten, co-founder and CEO, shares in this Opinion of the Week a few words about their strategy.

Additive Industries, a well-thought-out strategy

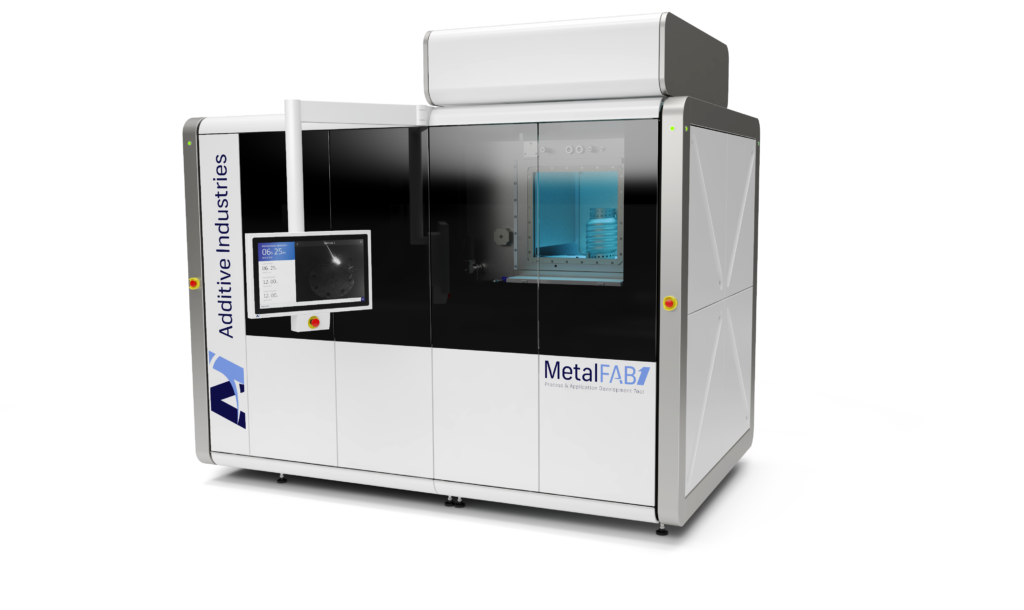

Additive Industries started in 2012 because the founders saw an opportunity in metal AM technology. Like several companies of the industry, the company developed a system that enabled it to take off. It is the MetalFaB1, a modular end-to-end powder bed fusion system that produces quality functional metal parts, and whose launch was carried out in 2015.

© Additive Industries

Speaking about this system, Additive Industries’ Daan Kersten explains that the integration of automation, the advanced laser calibration technology that can be pre-programmed to automatically run at specified intervals as well as the 4 lasers & 6 different modules are three characteristics that enable the system to distinguish itself from others of the same range.

In addition to this system, the Additive World Platform is also supplied to clients. It integrates a MRP system and enables the storage, sharing and analysis of data in order to meet demanding industrial markets requirements.

“After the launch, we started to develop our business at the international level and in various industries”, explains Daan Kersten. “Partnerships were signed with various players of the industry (the latest one released being the partnership with GKN Aerospace Global Technology Center in Bristol) and centers were opened to foster the development of the technology, processes and applications in strategic areas.”

Today, the company counts a center in Bristol (UK) that focuses on materials; another one in California dedicated to certified manufacturing, the one in Singapore that focuses on industrialization, not to mention the center of Eindhoven that aims to continue the development of hardware and software capacities.

Markets & applications

Even though the company is active in several markets, Daan Kersten confirmed that, for Additive Industries, the most demanding markets today are aerospace and automotive as well as the medical implants industry.

However, the CEO points out that “there is also a very large opportunity in the oil & gas segment.” “We are currently working on a project in this industry”, he adds. Without revealing more, the founder brings out a few differences between these sectors of activity: “Every market has its own requirements. Aerospace requires mainly light-weight parts, automotive is looking for reduction of costs. As for the Oil and gas segment, it is a combination of common features. One reason why this market stands out from the crowd is the fact that we can print parts on location; not to mention that interesting applications including impellor-parts in pumps.”

Outlooks for 2019

The company has made a good start to the year in the UK and in Singapore. As far as markets are concerned, the main industries they will target there are the aerospace sector, high performance automotive industry in the UK, semicon equipment as well as the oil & gas segment in Singapore.

At the hardware and software levels, they plan to launch an updated version, additional modules of their system at the next Formnext, at the end of this year.

In the meantime, given their recent hires, and the 25 open positions worldwide, one can already affirm that Additive Industries has completely emerged from the startup phase and is accelerating towards its goal: a Top 3 position in the industrial additive manufacturing market.