Farsoon revealed its expansion into the Southeast Asian footwear market by partnering with Chanhon Additive Manufacturing Technology Co., Ltd. (Chanhon Tech) in October 2023. Chanhon is a 3D printing solutions provider in additive footwear technologies, such as scanning, 3D printing & data processing.

Anugerah Cipta Mould Indonesia (ACMI) is a mold manufacturer in Indonesia that operates various Farsoon machines & advances its global footprint by launching the latest AM center.

Also, they have gained a trustable bond with footwear brands worldwide to offer multiple production parts such as outsoles, midsoles & TPU soles compiled with high-quality industrial standards.

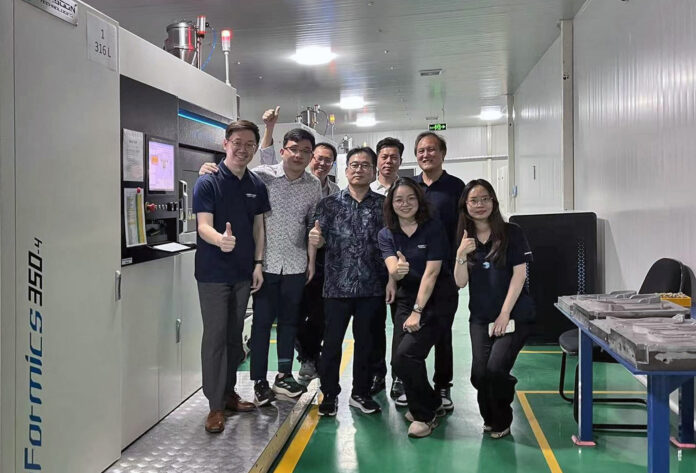

Min Seo Kang, ACMI’s lead manager for Metal 3D printing states, “As early as 2015, we began using SLA 3D printing for casting. With the growing demand in the metal market, we invested in Farsoon’s FS200M dual-laser system in 2021, making us the first manufacturer in Indonesia to operate a metal powder bed fusion machine for shoe molds and other industrial applications. We continue focusing on shoe mold manufacturing and future expansion to other industries, the larger FS350M quad-laser system has become our go-to solution for accelerating series production. Farsoon’s fast and professional technical support helped us master the operational processes and launch our application projects with an impressively smooth learning curve.”

After spending years in metal additive manufacturing, ACMI has finally decided to extend a dedicated AM Center in Indonesia. The primary focus is expanding the service capabilities by portraying a series of perks & opportunities offered by metal powder bed fusion technology.

It also includes quicker lead times, high quality, and modern design possibilities in a budget-friendly way compared to traditional manufacturing concepts. The AM Center will be a hub to push these advanced benefits to the global market.

“With Farsoon’s open parameter system, we can easily customize the processing and implement improvements. We have also collaborated with various industries, producing spare part models for automotive, marine, and cooling channel-integrated automated robots. With our FS350M machines currently running production with 316L (stainless steel) & AlSi10Mg (aluminum) material, we are excited about expanding our manufacturing capabilities at the upcoming AM Center,” Min Seo added.

Binghua Lu, General Manager of Chanhon Tech explains, “We are thrilled to collaborate with ACMI in the footwear sector and witness how Farsoon’s metal 3D printing technology has revolutionized Indonesia’s footwear manufacturing. With over a decade of experience in the footwear industry, we are proud to provide fast, responsive local technical support to meet the demands of series production.”

Farsoon is eager to partner with industry leaders to discover how 3D printing can transform footwear manufacturing. In August 2024, the adoption of Farsoon’s metal 3D printing solutions paved the way for the sustainable production of more than 100 million pairs of shoes.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.