3D printing is undergoing a paradigm shift with the development of the PNIPAM method. This method developed by researchers at The University of California San Diego involves the use of a polymer ink and saltwater solution to create parts.

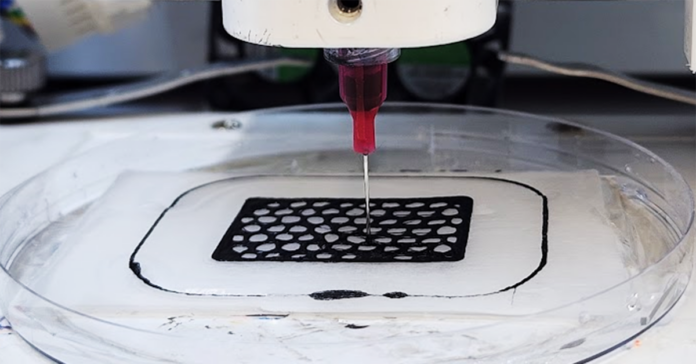

The liquid polymer solution is known as poly(N-isopropylacrylamide), or PNIPAM for short. According to researchers, when this PNIPAM ink is extruded through a needle into a calcium chloride salt solution, it instantly solidifies as it contacts the salt water.

When the salt is added to the polymer solution, the salt particles attract water molecules because they have a strong pull on them.

As a result, the water is pulled away from the polymer, leaving the polymer chains with less water around them. The polymer chains come together tightly, forming a solid without any water. This process is called the “salting-out effect.”

Implementing functional materials such as graphene flakes or carbon nanotubes can be possible. The salting-out effect is reversible. Another advantage of this technique is that the printed solid objects can be converted to usable liquid PNIPAM.

With the introduction of the PNIPAM method, it’s possible to conduct polymer 3D printing at room temperature. There is no need for post-print chemical usage as these chemicals are harmful to the environment and people.

A circuit board for powering a light bulb was created using this technique. The printed circuit is water-soluble as it’s dissolved in freshwater. This can help in recycling polymer materials.

Introducing this type of 3D printing technique opens up the possibilities of maximizing resources, minimizing waste, and making sustainable polymer materials using 3D printing techniques. It can radically affect the future of 3D printing by eliminating the need for specialized equipment, toxic chemicals, and energy-intensive processes.

You can access the full research here.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.