The EU-funded INKplant project made up of 19 interdisciplinary partners ambitions to produce 3D printed patient-specific implants to treat various pathologies affecting the elderly.

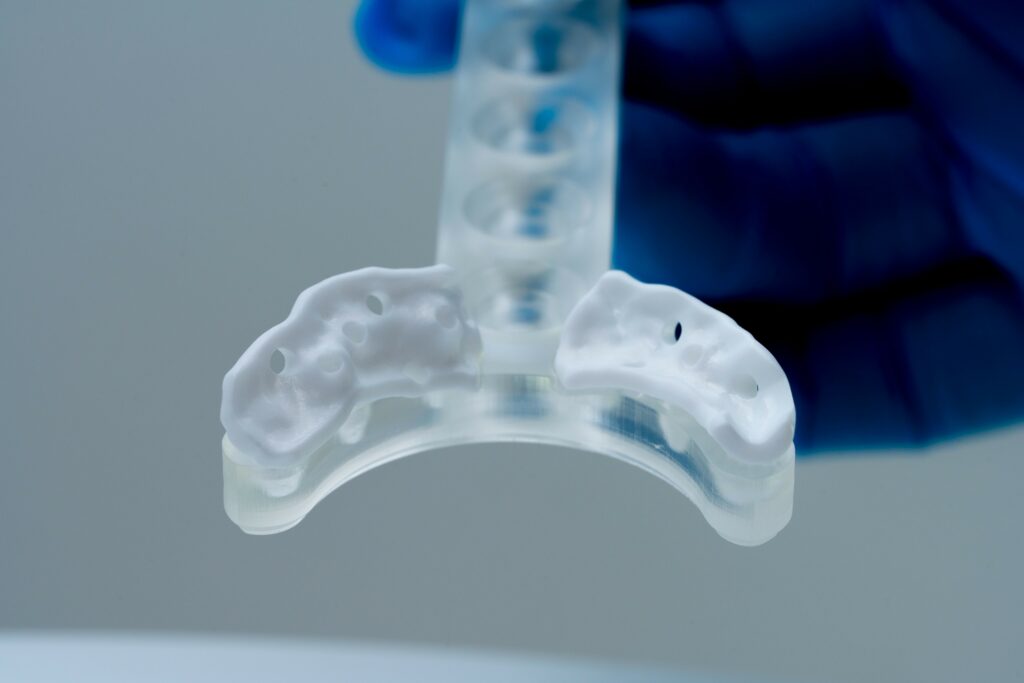

The project led by Profactor GmbH recently saw the implantation of a 3D printed

ceramic subperiosteal jaw implant in a patient. Described as a first, the team relied on Lithoz LCM technology to manufacture the implant.

The importance of the manufacturing process and the material selected

A patient at Kepler University Hospital, having previously lost multiple dental implants and bone grafts due to compromised health, was unable to undergo additional conventional surgical procedures due to extensive scarring. As a result, he received the new implant as a compassionate use case.

For those who are not familiar with LCM, please note that the Lithography-based Ceramic Manufacturing is a fabrication process where ceramic particles are dispersed in a photosensitive resin and this dispersion is thereafter solidified by light layer-by-layer to form a part. Then the part undergoes a sintering process to develop its ceramic properties and can be used for its final purpose.

One of the challenges of the manufacturing process was to achieve an optimal fusion of different biomaterials with LCM 3D printing. OEM Lithoz that completed the production, explains that after the loss of the teeth, the jawbone disappears as well, resulting in atrophic jaws and rendering the use of dentures impossible.

With the use of biocompatible high-strength zirconia, the implant did not require any bone augmentation. Only one procedure was performed, reducing this way the healing time by an estimated 75% and avoiding excess trauma for the patient.

Despite some anticipated wound healing issues post-surgery, the exceptional soft tissue compatibility of zirconia compared to titanium proved to be remarkably effective. After 60 days, the implant demonstrated clinical stability, marking a significant advancement in the treatment of severely atrophic jaws.

Thanks to this synergetic innovation in design and material, all the necessary surgical procedures were completed in a single operation, Lithoz confirms.

Read more news on Lithoz here.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com