Aerospace company Proteus Space recently announced it completed a successful on-orbit payload deployment in collaboration with NASA’s Jet Propulsion Laboratory (JPL). Other collaborators on the mission include SpaceWERX, Air Force Research Laboratory, Leonardo DRS and University of California.

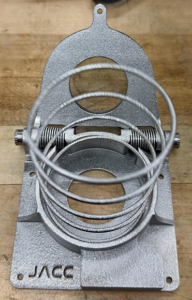

(Courtesy Douglas Hofmann / NASA JPL)

The mission used the JPL Additive Compliant Canister (JACC), a deployable mechanism based on helical antenna systems, demonstrating how additive manufacturing can simplify compliant mechanisms and deployable structures.

Proteus explains that the the jack-in-the-box–style system is about the size of a small paperback book when stowed and weighing under 500 grams. It integrates its lid, canister, hinges, torsion springs, and deployable compression spring into a largely monolithic titanium structure, reducing the part count by a factor of three compared with conventional designs.

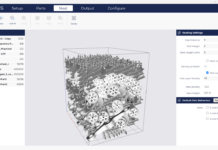

The system also features a novel, embedded kinematic hinge architecture. Developed and produced in-house at JPL in less than a year from napkin sketch to delivery, JACC leverages the laboratory’s advanced additive manufacturing capabilities, the company says.

Its successful on-orbit demonstration aboard the Proteus Space M1 ESPA class satellite underscores the utility of 3D printing for advanced deployable systems on future space missions.

*We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.