With nearly 37 million consumer product parts 3D printed in 2023—a 7 million increase (+23%) compared to 2022—the question of whether the consumer goods sector is driving the adoption of Additive Manufacturing (AM) is no longer up for debate. Yet, this sector is traditionally defined by mass production, whereas AM is best known for its ability to deliver tailor-made solutions. This apparent contradiction raises a key question: how can AM enable customization at scale? Michael Simmons, Advanced Application Engineer at 3D Systems and Manager of the Application Development Lab in Berkeley, CA, shares his insights with 3D ADEPT Media.

One of the biggest dilemmas consumer brands face is choosing between the easy, cost-efficient manufacturing of standard goods and the complex, high-cost production of individually customized products. Traditionally, it’s been an either-or scenario—scale or personalization. Additive Manufacturing removes this trade-off from the equation.

The technology unlocks new levels of creativity and innovation across eight major consumer product segments: eyewear, footwear, sports equipment, consumer electronics and technology applications, toys and entertainment, fashion, design products (such as furniture and lighting), and jewelry.

3D ADEPT Media has explored numerous applications of 3D Systems’ technology in several of these areas, but the OEM particularly excels in delivering consumer technology applications at scale. Highlighting applications with the highest demand for customization enabled by AM, Simmons notes: “There is growing anticipation that wearables, audio, and AR/VR applications will converge, with headsets and smart glasses forming an interconnected, cohesive ecosystem.

Of all the applications enabled by 3D Systems’ AM, one we remain in awe of is these HYLIXA 3D printed speakers, which deliver sound “as if the artist was in the room”.

For the Advanced Application Engineer, mass customization, in the context of consumer technology, can be defined “as the creation of individualized products tailored to a specific end user while being efficiently scaled for full production to serve a medium- to large-volume user base.” This would mean enabling brands of the sector to “produce personalized or bespoke components at scale—without the need for traditional tooling—by using advanced 3D printing technologies that combine the flexibility of customization with the efficiency of mass production.”

Although this definition could easily apply to other applications, we believe it’s crucial to assess the key enablers that would make this process a tangible reality.

The key enablers for a mass customization strategy with AM

According to research, OEMs often explore four major strategies for implementing mass customization: combining AM with conventional manufacturing, integrating customer-centred design, establishing flexible manufacturing networks, and creating adaptive production systems. This would mean relying on an indirect 3D printing approach to deliver products at scale.

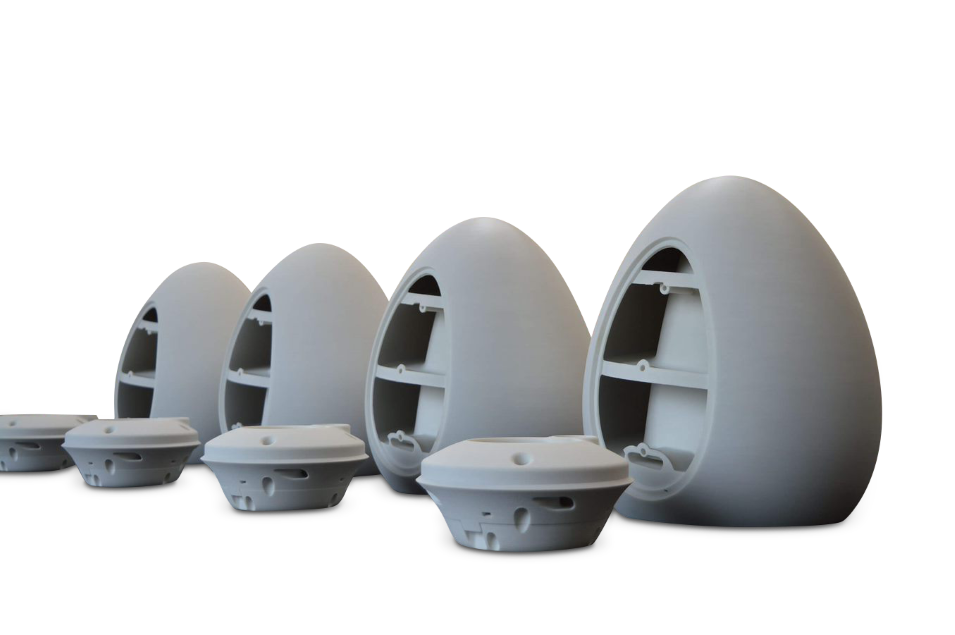

“Indirect processes like digital eggshell tooling allow customizations of end-use silicone parts without expensive tooling. 3D Systems leverages SLA, PSLA, Figure 4, and MJP to create the digital tooling. With this indirect process, the end customer can integrate seamlessly with their current validated silicone. No compromise on meeting silicone requirements such as biocompatibility and chemical resistance. SLS platforms allow the use of conventional thermoplastics that designers and engineers are familiar with,” the expert explains.

A more detailed view of this approach emphasizes the need for multi-material capabilities, integrated digital workflows, and advanced process monitoring – all considerations 3D Systems takes into account and more, to balance customization with operational efficiency.

Our conversation with Simmons highlights 5 strengths that help the company stand out in the consumer technology space: a broad additive manufacturing portfolio, materials science expertise, integrated software workflow, proven track record in regulated and high-volume markets, partnership ecosystem & vertical expertise.

The manufacturer’s comprehensive range of AM processes (SLA, SLS, projector-based technology, MJP, etc.) allows for a “mix & match” opportunity and the ability to deliver application-specific materials (biocompatible resins, high-impact polymers, etc.) that meet consumer product requirements like durability, aesthetics, and safety compliance. That said, this approach does not necessarily remove the challenges of ensuring repeatability and quality when producing individualized components at scale. As a matter of fact, “the congruency of post-processing during clean, cure, and metrology”, is one challenge often faced, Simmons emphasizes, but “shifting the manual process to semi-automated/automated workflows removes variability in the process.”

3D Systems’ software 3D Sprint®, 3DXpert, and Oqton help to streamline the design-to-manufacture process, automating customization, nesting, and production planning at scale.

Additionally, the company builds on its existing capabilities in other sectors. By expanding customization in demanding and regulated fields like healthcare and connectors, this expertise can easily be applied to consumer markets such as wearables or sports gear.

One compelling example is a customer using a fleet of semi-automated Figure 4 production printers to produce sacrificial tooling tailored to individual anatomical features. Since each user is unique, the tooling must be customized—and AM makes this both fast and cost-effective. At a production volume of one, additive manufacturing reduces the unit cost by up to 95%, making the business model economically viable. This example from healthcare can easily be applied to consumer technology applications.

Last but not least, brands that leverage a traditional manufacturing approach often need to rely on a strong supply chain to avoid disruptions. With today’s volatile world, AM proves to be a safer option to explore as it provides the flexibility to produce either at scale or on demand, regardless of the final consumer’s location. To do so, 3D Systems partners with OEMs, consumer brands, and service bureaus, helping integrate additive manufacturing into existing supply chains.

AI: An opportunity or a limitation?

Mass customization in the age of AI is almost an inevitable topic. While there are many dimensions to explore, one particularly relevant angle here is how far this technology can take mass customization. As a consumer, for instance, am I truly able to specify what I want—both in terms of aesthetics and functionality?

For Simmons, the answer is yes: “AI can automatically analyze consumer data (preferences, biometrics, usage patterns) to generate personalized designs in real time. Generative design algorithms can instantly create product variations that are optimized for fit, function, and aesthetics—from custom footwear to ergonomic wearables—without manual redesign.”

In markets like wearables, eyewear, or sports gear, AI can help ensure predictive fit and performance by analyzing scans of a person’s anatomy to generate perfect-fit designs while ensuring they meet durability and comfort standards, he emphasized.

For engineers, the expert identifies a threefold benefit when integrating AI into additive manufacturing:

First, design optimization beyond human capability: generative design tools can explore thousands of permutations simultaneously, optimizing for factors like weight, strength, material efficiency, and even environmental impact. The result is lighter, stronger, and more unique geometries—designs that are only feasible through additive manufacturing.

Second, rapid feedback loops and co-creation: AI-driven design platforms enable interactive configurators where consumers can tweak product features in real time, while the system ensures those designs remain manufacturable. This not only boosts consumer engagement but also supports efficient, personalized production.

Finally, adaptive manufacturing workflows: AI can anticipate production bottlenecks, auto-generate support structures, and optimize build layouts for higher throughput. For highly customized, low-volume runs, AI also enhances scheduling and quality control, helping maintain repeatability and reduce cost per part.

In a nutshell…

As consumer demand for personalized, high-performance products continues to rise, 3D Systems’ additive manufacturing solutions stand out for turning complexity into a competitive advantage. What’s especially clear is the company’s ability to bridge the gap between mass production and mass customization through its versatile AM platforms and adaptive manufacturing workflows.

That said, consumer technology remains one of the sectors where AM is still largely outsourced. Looking ahead, a key question remains: what kind of business model could bring customization at scale in-house? That’s a conversation we’re eager to explore next.

This content has been produced in collaboration 3D Systems.