Aligned with its goal of facilitating printing with 100% recycled materials directly from raw pellets, Italian machine manufacturer WASP introduces a new pellet 3D printer: the WASP CUBO HDP.

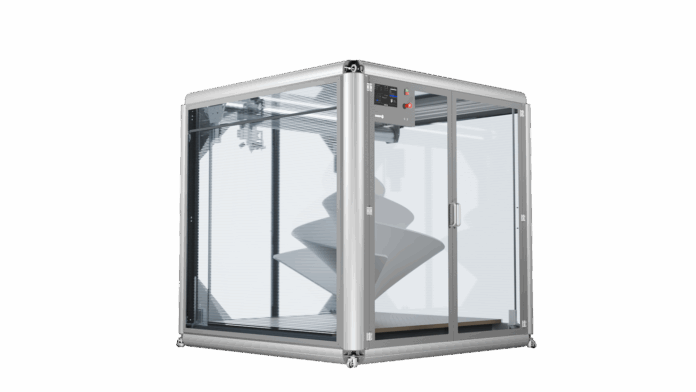

Designed for large-scale production, the 3D printer is entirely designed and manufactured in Italy in the company’s laboratories. Built to ensure maximum productivity and versatility, even with complex materials such as microplastics and shredded plastics, the machine features a print volume of 120 x 120 x 120 cm.

It ensures low power consumption (with an average power consumption of 450 W and a maximum power-on load of 1 kW), efficient powder recycling, and is said to be ideal for demanding production environments.

Key features of the 3D printer

WASP CUBO HDP is compatible with the RIGENERA 3D extrusion system, which allows to print directly from in-house recycled shredded plastics. Unlike traditional extruders that only work with pellets and can be damaged by metal, RIGENERA extruders are redesigned to accept shredded plastic in various sizes. These extruders are optional when buying the machine.

Additionally, the powder recirculation system always keeps particles in motion, ready for printing without waste. Thanks to this continuous flow, even powders that would be trapped by traditional filters can be used efficiently, maximizing the reuse of recycled material. Thanks to this technology, you can truly recycle, including even the smallest particles.

Other interesting features include the mechanical clamping of the bed, a rechargeable filtration system to ensure a safe working environment – especially when working with impure or recycled materials, the ability to print non-proprietary materials, and an auto-feeding system.

The 3D printer’s design supports both pre-assembled shipping or onsite assembly.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com