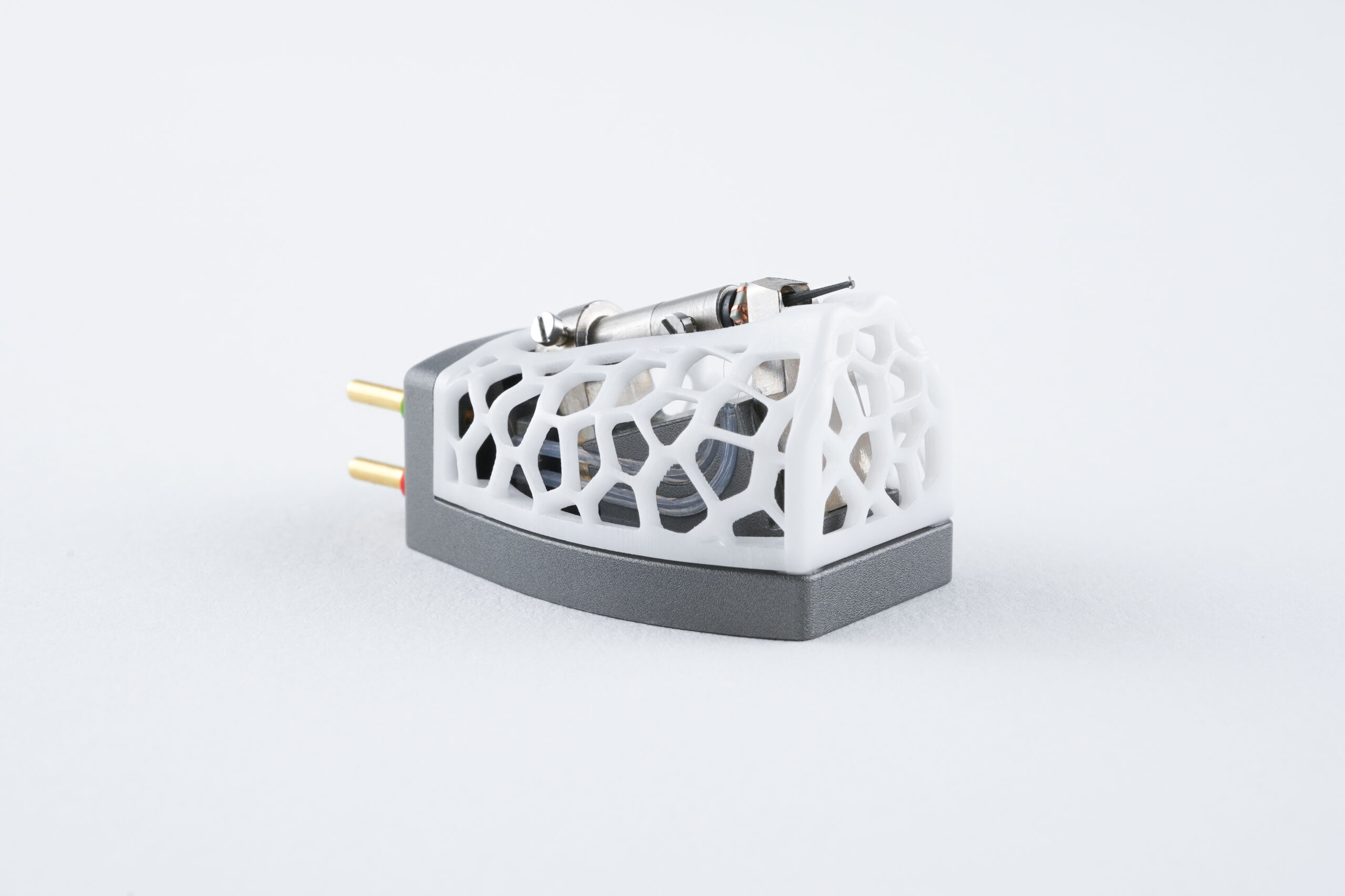

“X-quisite VORO”, a monoblock moving-coil (MC) cartridge commercialized by HiFiction AG, is encapsulated by a fully 3D-printed single-piece ceramic Voronoi-web housing.

Described as a “world’s first” monoblock MC cartridge, the application marks the first use of Lithoz’s LCM (Lithography-based ceramic manufacturing) technology in consumer goods technology.

The cartridge is a product of HiFiction AG, under their X-quisite brand. HiFiction AG is an expert in the development and production of precision and micromechanical products for high-quality music reproduction.

The capsule was manufactured by Germany-based ceramic 3D printing specialists Steinbach AG, a prototyping services company that acquired its first Lithoz 3D printer in 2020.

Manufactured in one piece with no support structures or post-processing at all

Steinbach AG manufactured its Voronoi web-shaped zirconia capsule, which comes as a support-free, single-piece item. This housing is engineered to meet stringent mechanical and acoustic specifications while also serving as a key aesthetic element in the design of this high-end part.

HiFiction AG’s expectations for the housing were to reach “perfection in resonance behavior and lightweight construction whilst providing an exceptional aesthetic experience”.

Steinbach AG manufactured the skeletonised, nature-inspired single-piece zirconia housing that sits completely contact-free above the needle and comes without any joints or assembly.

The housing combines maximum rigidity with minimal sensitivity to airborne sound, strongly supporting the entire monoblock cartridge. It helps remove the acoustic leaks arising between attachment points by uniting the needle carrier and coil body.

During the development phase, metals and plastics failed to meet the envisioned sweet spot between design, weight and sound behavior. Steinbach AG recommended zirconia as the material of choice to best meet those requirements.

Due to the intricacy of nature-inspired design, including cantilevered features and hard-to-reach internal surfaces, manual finishing was not an option. Consequently, the ceramic component was designed for precise sintering, with the geometry defined to ensure stress-free production without the need for support structures.

With external dimensions of 17.70 x 21.90 x 11.45 mm, the component highlights wall thicknesses of less than 1 mm and tolerances within ± 50 µm, hence meeting the extreme quality requirements of high-end audio engineering.

Each component was produced with a layer thickness of 25 µm with 15 parts per build platform on average, which enabled economically viable small batch serial production of around 100 units. The resulting component is not only a significant technological achievement, but also a functional work of art, Lithoz says in a press communication.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.